Application of SOLIDOT remote I/O modules in the field of automatic spray painting robots

A spray painting robot is a robot that can automatically complete surface spray painting operations, with the advantages of high efficiency, precision, stability, and energy saving. A spray painting robot is usually composed of a mechanical arm, a control cabinet, an operation panel, a spray gun, and a feeding system. It is mainly used in the automotive, aerospace, electronics, chemical, light industry and other industries, which can improve production efficiency and quality, and reduce costs and pollution.

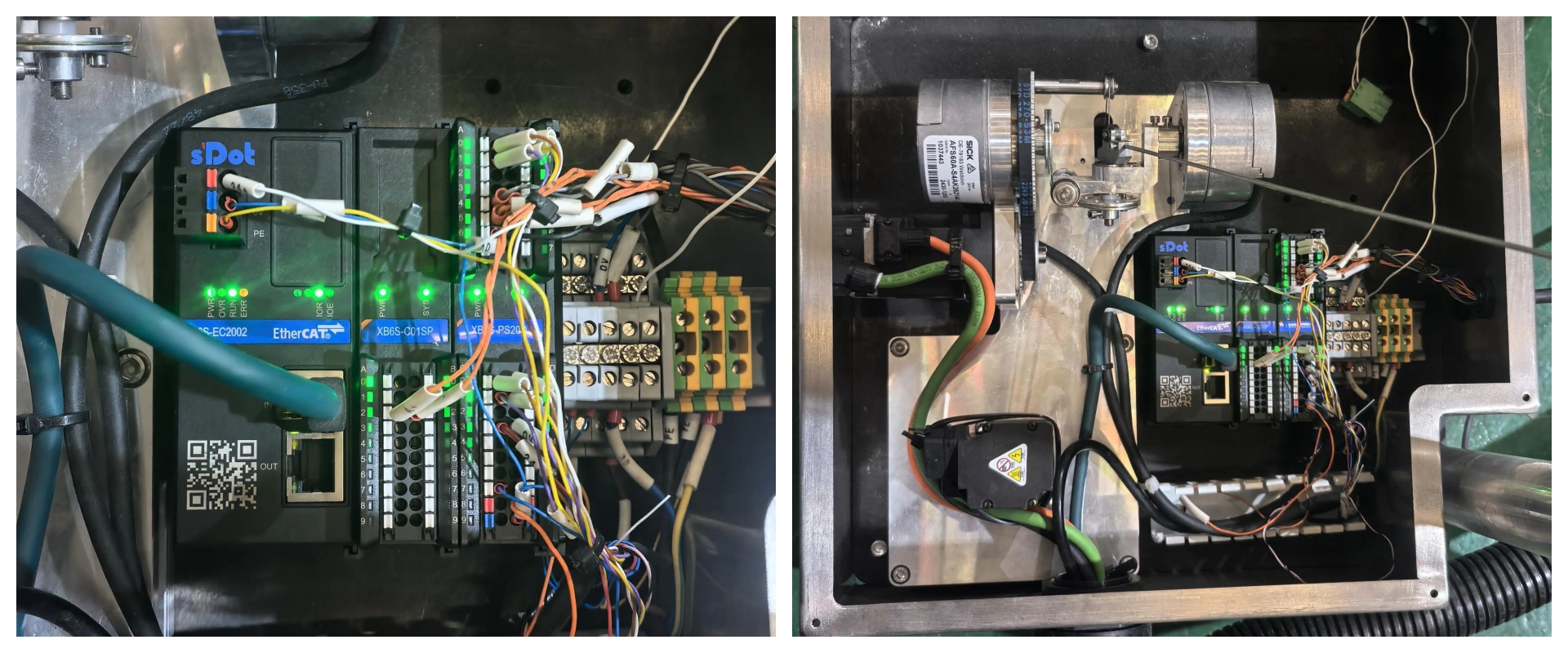

The products used in this case study are XB6S-EC2002 , XB6S-PS20D , XB6S-C01SP from SOLIDOT.

Production process introduction

Spray painting robot workflow: positioning - data recording - monitoring system

【Position】

The robot needs to be accurately positioned and moved to the area that needs to be sprayed.

【Data Recording】

The control system needs to record the data of each spraying, including paint flow, spraying time and location and other related information.

【Monitoring system】

The control system needs to identify faults in a timely manner through detection sensors, and record fault information and stop the robot operation in a timely manner through the alarm system and fault recording function.

Current pain points

Traditional robot spray printing solutions require engineers to reprogram when changing products, and there is high threshold of use. Customers need an effective programming-free control system for spray printing robots: the robot can run according to the trajectory after the manual calibration instrument is used to teach the trajectory once, without the need for engineers to program; in order to accurately record the motion trajectory of the teaching process, the system also needs to be able to accurately collect the absolute coordinates and coordinate posture of each motion node, and have good anti-interference ability.

I/O module application

The equipment uses the EtherCAT bus protocol for communication. The SSI encoder is responsible for collecting the absolute coordinates taught by the calibrator. The same coordinate point can have different postures, so a gyroscope is required to collect the coordinate posture. The XB6S-PS20D absolute encoder counting module of SOLIDOT can accurately and quickly collect the absolute coordinates measured by the SSI encoder.

The gyroscope is integrated inside the calibrator and supports Modbus communication. Through the serial communication module XB6S-C01SP, the calibrator can be connected to the EtherCAT bus system.

Product Advantages

The serial communication module XB6S-C01SP of SOLIDOT supports three communication interfaces: RS485/RS422/RS232, and supports multiple communication modes: Modbus RTU master-slave, Modbus ASCII master-slave, and Freeport. It takes up little space, has simple configuration, and runs stably. SOLIDOT also has integrated serial communication modules PN4-GW2MR and PN4-GW2FP for selection, which can realize the conversion between PROFINET protocol and Modbus RTU and Freeport.

From left to right:

SOLIDOT integrated serial peer module PN4-GW2MR

SOLIDOT plug-in serial communication module XB6S-C01SP

SOLIDOT integrated serial peer module PN4-GW2FP

The plug-in encoder counter module XB6S-PS20D of SOLIDOT supports dual-channel SSI absolute encoder input and has a probe latch function. There are also plug-in encoder counter modules for incremental encoders: XB6S-PL20 supports dual-channel 24V single-ended signal input, and XB6S-PL20D supports dual-channel 5V differential signal input. XB6S-PL20 and XB6S-PL20D support multiple pulse input modes such as AB orthogonal (ABZ), direction pulse (Pul+Dir), and dual pulse (CW/CCW), and support multiple functions such as reporting channel real-time speed, probe latch, and comparison output.

From left to right:

SOLIDOT plug-in SSI absolute encoder counting module XB6S-PS20D

SOLIDOT plug-in single-ended Incremental encoder XB6S-PL20

SOLIDOT plug-in incremental encoder module XB6S-PL20D

SOLIDOT's I/O module product system is complete and applicable to a wide range of scenarios. It can meet the different needs of customers on site to the greatest extent and provide customers with a better user experience.

Recommended Products

XB6S-PS20D

2-channel SSI absolute encoder counting module

XB6S-PL20

2-channel single-ended incremental encoder counting module

XB6S-PL20D

5V 2-channel incremental encoder counting module with differential signal

PN4-GW2MR

PROFINET to 232/485/422 Modbus RTU protocol

XB6S-C01SP

XB6S Series Serial Communication Module

PN4-GW2FP

PROFINET to 232/485/422 Free Port Protocol