The application of Solidot's remote I/O module XB6S in waste emulsified liquid treatment equipment

Waste emulsified liquid treatment equipment is an environmentally friendly device that efficiently processes waste emulsified liquids through high-temperature and high-pressure treatment, gas-liquid separation, and oil-water separation technologies. This equipment utilizes a high-temperature and high-pressure environment to allow some volatile gases in the emulsion to escape, and then employs physical separation techniques to thoroughly separate the oil phase from the water phase. The oil phase is recovered for reuse, while the treated water phase meets discharge standards. It is widely applied in industries such as machining, metal manufacturing, and automotive manufacturing, featuring high processing efficiency, high resource recovery rates, and strong environmental protection.

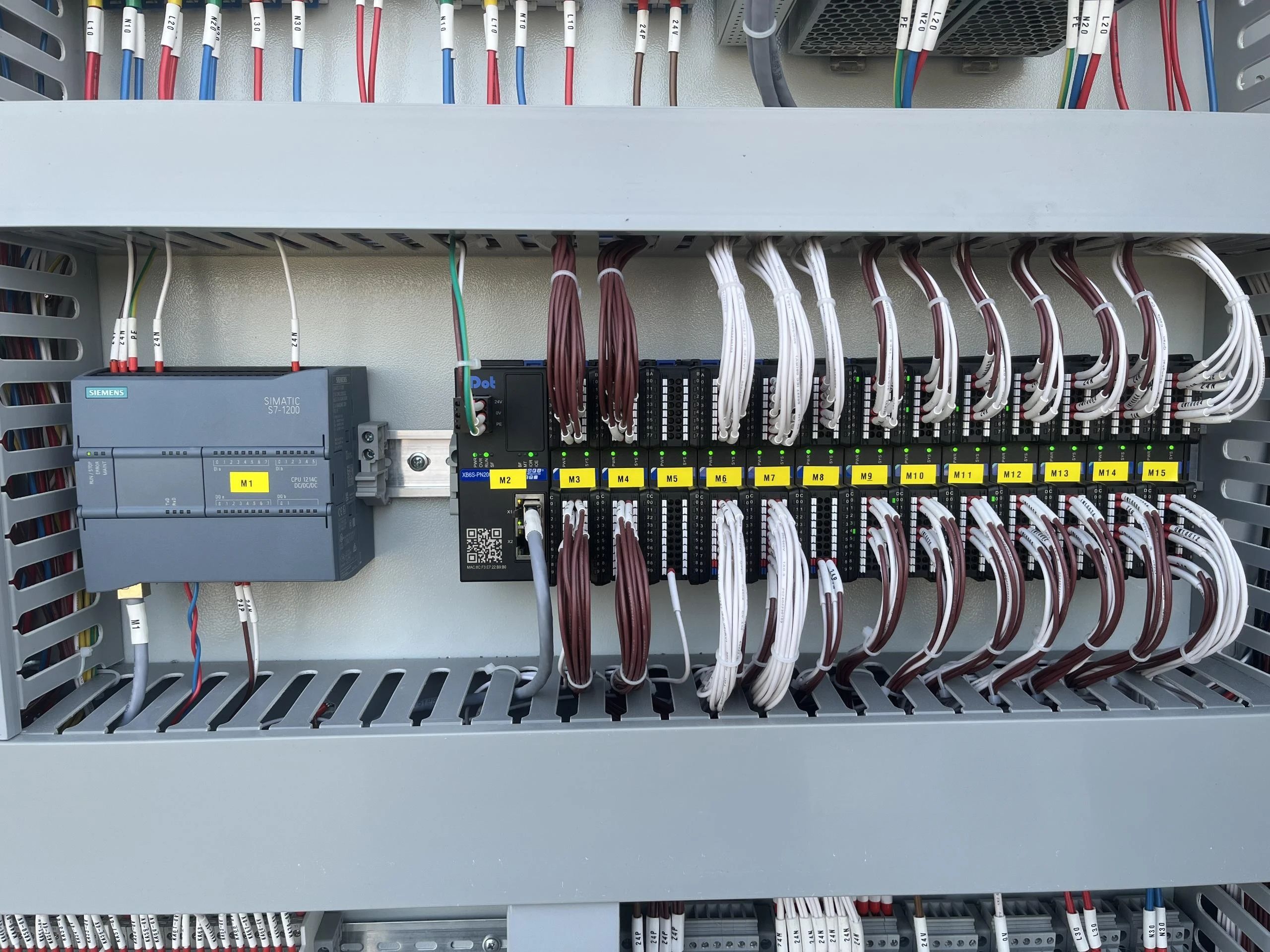

The Solidot products used in this case include XB6S-PN2002, XB6S-3200, XB6S-0032B, XB6S-A80I, XB6S-A08I.

I. Production Process Overview

The workflow of waste emulsified liquid treatment equipment is: Feeding → High-temperature high-pressure treatment → Gas-liquid separation → Oil-water separation → Oil recovery → Water treatment and discharge.

[Feeding]

After pre-treatment, the waste emulsified liquid enters the high-temperature compression unit via a pumping system.

[High-temperature High-pressure Treatment]

In the high-temperature and high-pressure environment, some volatile components in the emulsion, such as moisture and solvents, partially vaporize, forming a gas-liquid mixture.

[Gas-liquid Separation]

The gas-liquid mixture enters the separation tank, where pressure adjustment achieves the preliminary separation of gas and liquid. The gas is condensed for recovery or harmless treatment.

[Oil-water Separation]

The remaining liquid enters the oil-water separation unit, utilizing differences in density and centrifugal techniques to completely separate the oil phase from the water phase.

[Oil Recovery and Water Treatment]

The separated oil phase is transported to a storage tank for reuse, while the water phase enters the water treatment system, undergoing neutralization, filtration, and other processes before being discharged according to standards.

II. Application of I/O Modules

The equipment employs PROFINET bus protocol communication, with digital input/output modules XB6S-3200/XB6S-0032B and analog input/output modules XB6S-A80I/XB6S-A08I connecting to the PLC through the PROFINET protocol coupler XB6S-PN2002.

The XB6S-3200/XB6S-0032B modules collect/output switch signals from devices, such as the start/stop of the feeding pump and the opening/closing of the gas-liquid separation tank exhaust valve. The XB6S-A80I/XB6S-A08I modules collect/output current signals from various sensors in the process, indirectly obtaining information about process parameters such as temperature, pressure, liquid level, and flow rate. They work in synergy, enabling real-time monitoring of the equipment, providing a basis for decision-making in the control system, and transmitting signals according to PLC instructions to drive actuator actions.

Compared to the customer's existing bus I/O solutions, Solidot's XB6S series remote I/O modules are more reliable and have stronger anti-interference capabilities. Additionally, the user-friendly wiring methods and convenient configuration operations shorten the deployment cycle of bus I/O and ensure the rapid implementation of the customer's project.

III. High-Reliability Remote I/O Module - XB6S Series Products

Solidot's XB6S series remote I/O modules are compatible with multiple bus protocols and feature function modules for motion control and temperature acquisition. The products have undergone strict EMC testing, showcasing strong anti-interference capabilities to prevent disconnection; they support diagnostics, alarms, and abnormal log recording, providing intelligent feedback and ease of use.

Recommended Products

XB6S-PN2002

PROFINET filedbus coupler module

XB6S-3200

32-channel digital input module, input NPN/PNP compatible, input filter default 3ms

XB6S-0032B

32-channel digital output module, output PNP type

XB6S-A80I

8-channel analog current input module, Single-ended signaling, adjustable range: Disable, 4mA~20mA, 0mA~20mA

XB6S-A08I

8-channel analog current output module, Single-ended signaling, adjustable range: Disable, 4mA~20mA, 0mA~20mA