Examples of applications for Solidot's Remote I/O XB6S PTO Pulse Output Module

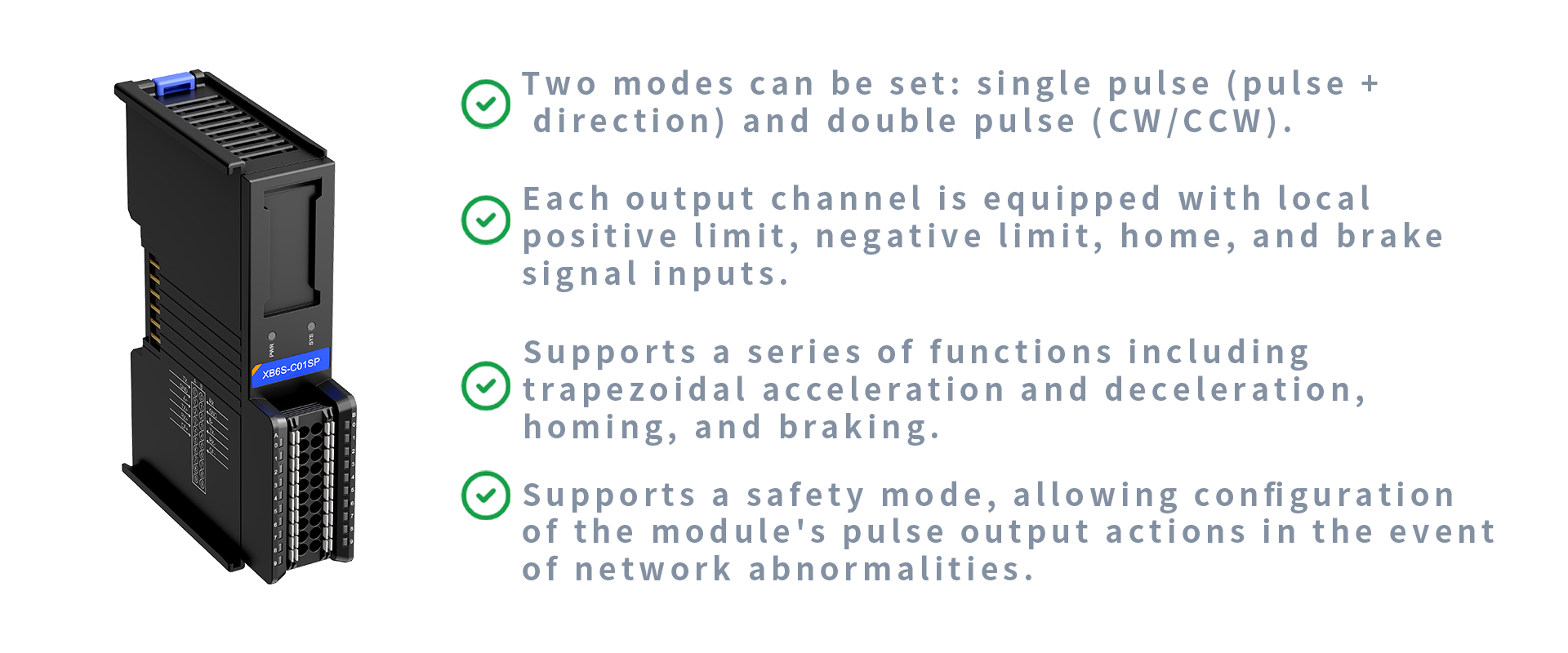

XB6S-PT04A is a 4-channel PTO pulse output module from the XB6S series, compatible with XB6S series couplers. It can be connected to external stepper/servo motor drivers and drives them by outputting pulse signals. The module has a total of 4 pulse output channels, each equipped with 4 input channels, resulting in a total of 16 input channels. This input-output combination can meet most driving scenarios for stepper/servo motors.

1. Application Example

The fully automatic battery casing cleaning machine is a precision device that integrates ultrasonic technology, automated control, and multi-process collaboration, primarily used for cleaning the battery casings of new energy vehicles. The XB6S-PT04A module can output pulses up to 200 kHz across 4 channels, driving high-frequency electromagnetic valves for instantaneous response in the spraying system, creating high-pressure water jets to tackle stubborn grease.

During the cleaning process, the tray cart loaded with components can rotate inside the cleaning chamber. The XB6S-PT04A module sends pulse signals to the stepper/servo motor, driving the turntable to achieve synchronized rotation, allowing all surfaces of the cleaning parts to be subjected to high-pressure water flow. The movement and positioning of the spray nozzle during cleaning are also accomplished through the XB6S-PT04A module in conjunction with servo drivers, achieving a movement precision of ±0.05 mm to ensure that the high-pressure jet accurately covers the grooves of the battery casing.

In addition to its extensive application in this cleaning machine, the XB6S-PT04A module is also widely used in industrial robot motion control, precision assembly line synchronization systems, and timed control in packaging machinery, thanks to its features such as high-frequency output, multi-channel capability, multiple pulse modes, and various motion modes.

Fully Automatic Battery Casing Cleaning Machine

Field Application of XB6S-PT04A

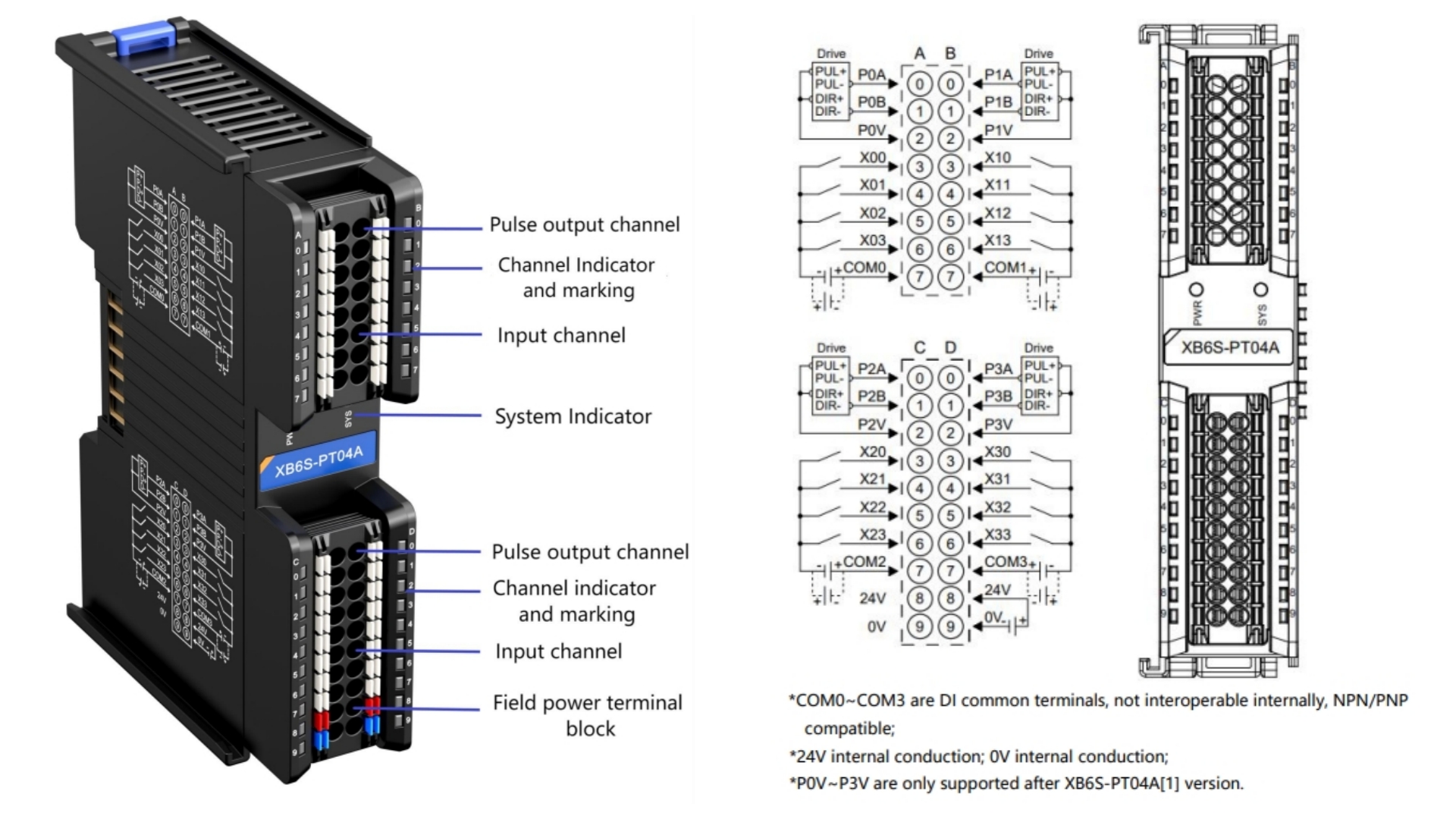

2. Panel Structure and Wiring Diagram

Left: XB6S-PT04A Panel Structure, Right: XB6S-PT04A Wiring Diagram

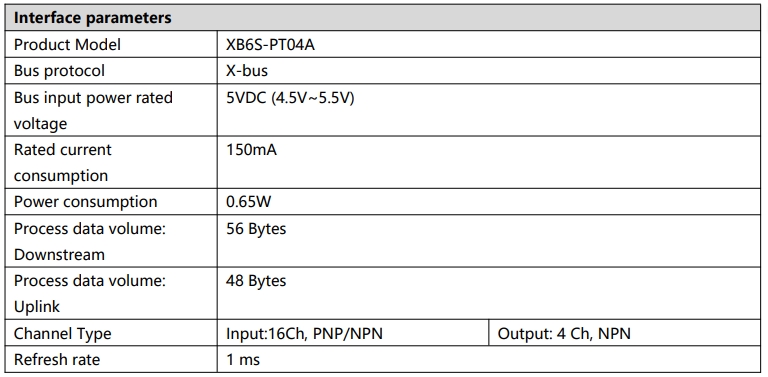

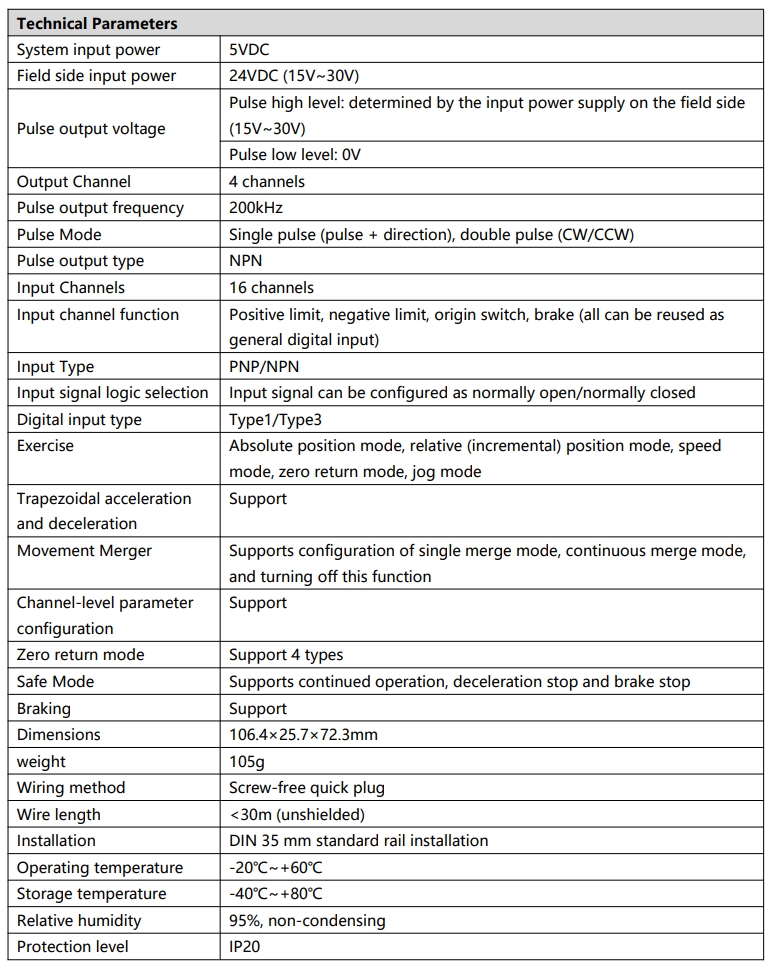

3. Parameter Overview