The application of Solidot's remote I/O modules in five-axis laser processing centers

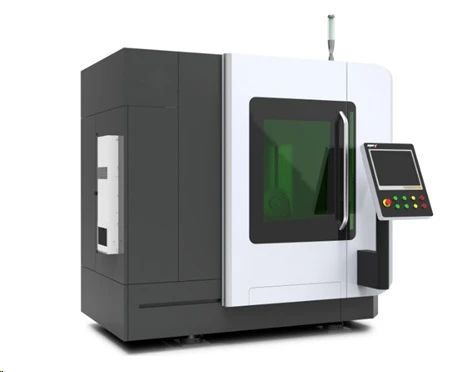

The five-axis laser processing center is a laser machining device used for cutting complex curved surfaces, which has been widely applied in the automotive manufacturing industry, particularly for high-strength structural components. It operates without the need for molds, has low costs, high efficiency, and significantly shortens the manufacturing cycle of automotive parts. Additionally, five-axis laser processing centers have found applications in aerospace, mold processing, and 3C electronics.

The five-axis laser processing center achieves five degrees of freedom through the coordinated motion of five independently controlled axes, utilizing a high-energy laser beam to melt, vaporize, or cut materials. The key control technology involves real-time adjustments of the position and speed of each axis to ensure that the laser beam can move precisely along the preset trajectory.

I. Processing Workflow

【CNC Programming and Path Planning】

Based on the 3D model, a five-axis collaborative processing path is generated to ensure that the laser head processes components at the optimal incident angle and constant focal length.

【Five-Axis Coordinated Motion】

Linear axes control the spatial position of the laser head, while rotary axes adjust the beam angle.

【Laser Processing Process】

The laser generator outputs a high-energy light beam, which forms a light spot after passing through optical devices. Meanwhile, sensors such as visual and infrared monitors the processing status, dynamically adjusting the power.

II. Application of I/O Modules

In the five-axis laser processing center, to achieve high-speed processing of multiple complex surfaces within a single clamping setup, key control aspects such as error compensation, dynamic matching, focal drift, and light speed maintenance are essential, requiring stable and efficient communication assurance. Therefore, to enhance interference resistance and maintain operational connectivity of I/O while ensuring the versatility of the serial communication modules, the customer ultimately chose Solidot's XB6S series products. Currently, the customer has successfully delivered multiple processing center projects, and the I/O system is operationally stable, receiving strong recognition from clients.

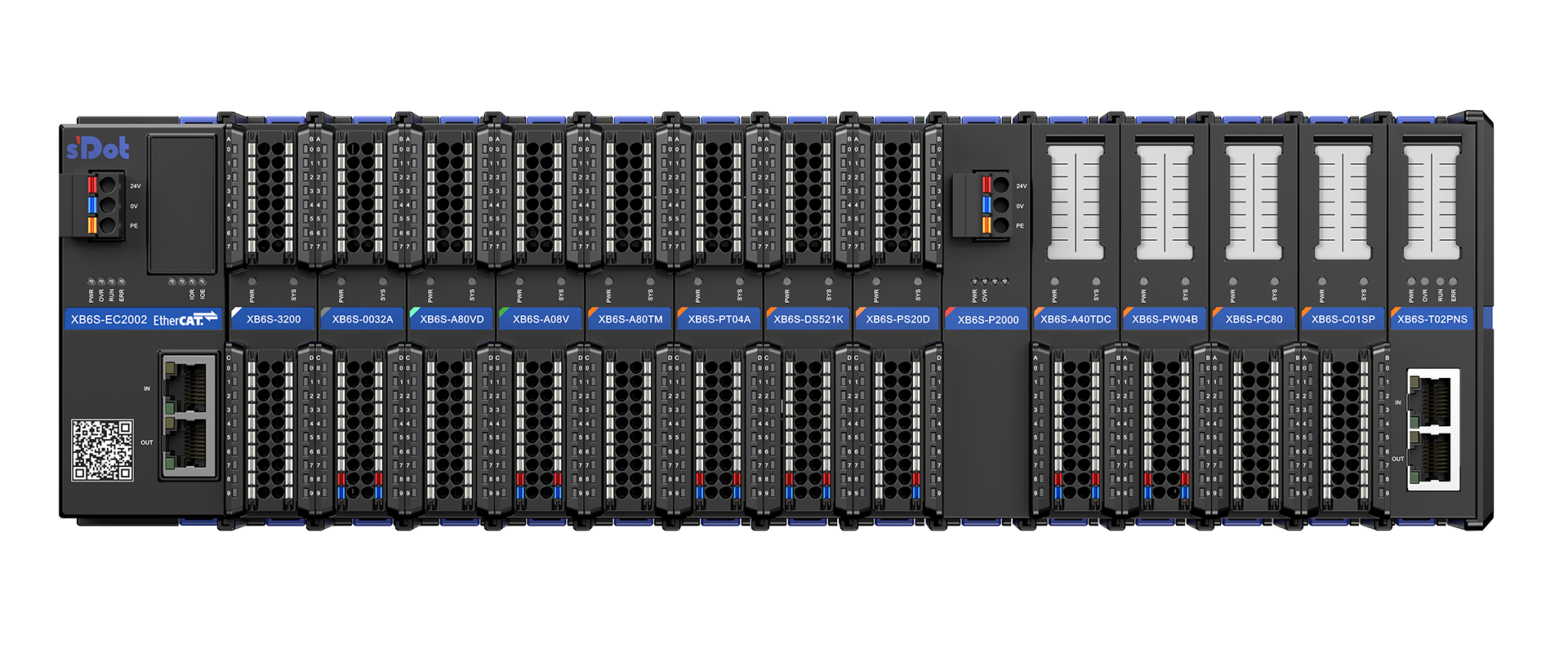

This processing center utilizes the EtherCAT bus protocol and is equipped with Solidot's remote I/O modules: EtherCAT coupler XB6S-EC2002, serial communication module XB6S-C01SP, 32-channel digital input module XB6S-3200, and 32-channel digital output module XB6S-0032B, as well as a 4-channel analog voltage input module XB6S-A40V, a 4-channel analog voltage output module XB6S-A04V, and a 4-channel temperature acquisition module XB6S-A40TM。

The digital input/output modules are responsible for signal acquisition and communication for detection, indicator lights, buttons, limit switches, and more. The analog voltage input/output modules are responsible for communication with voltage-related instruments. The XB6S-C01SP ensures accurate transmission of relevant commands, maintaining normal communication with the laser control card, while the XB6S-A40TM is tasked with collecting relevant temperature data, providing feedback on whether the temperature exceeds the preset range.

III. Highly Reliable Remote I/O Modules - XB6S Series Products

Solidot's XB6S series remote I/O modules are compatible with various bus protocols and feature function modules for motion control, temperature acquisition, and more. The products have undergone strict EMC testing, offering exceptional anti-interference capabilities and preventing disconnections. They support diagnostics, alarms, abnormal log recording, and smart feedback, making them user-friendly.

Recommended Products

XB6S-EC2002

EtherCAT filedbus coupler module

XB6S-C01SP

XB6S Series Serial Communication Module

XB6S-3200

32-channel digital input module, input NPN/PNP compatible, input filter default 3ms

XB6S-0032B

32-channel digital output module, output PNP type

XB6S-A40V

4-channel analog voltage input module, Single-ended signaling, adjustable range: Disable, -10V~+10V, 0V~10V, -5V~+5V, 0V~5V, and 1V~5V

XB6S-A04V

4-channel analog voltage output module, Single-ended signaling, adjustable range: Disable, -10V~+10V, 0V~10V, -5V~+5V, 0V~5V, and 1V~5V

XB6S-A40TM

4-channel thermal resistance and thermocouple temperature acquisition module