The application of Solidot's remote I/O module XB6S in the smart logistics conveyor system for cardboard packaging

The smart logistics conveyor system for cardboard packaging is a core component of the entire process of cardboard production, transportation, and warehousing. Its efficiency, precision, and traceability directly impact the operational efficiency and cost control of enterprises. Solidot's remote I/O module series XB6S provides critical support for signal acquisition and command execution in this system with its high reliability, flexible expansion, and intelligent diagnostic features.

Products used in this case from Solidot: XB6S-PN2002, XB6S-1600, XB6S-0016B

1. Production Process Overview

Workflow of the smart logistics conveyor system: cardboard enters the buffer zone → track vehicle transfer → conveyor belt connection → elevator warehouse entry.

[Cardboard Enters Buffer Zone]

After the cardboard is shaped, it is pushed to the designated buffer zone by the end of the production line, triggering the logistics system start signal.

[Track Vehicle Transfer]

Upon receiving dispatch instructions, the track vehicle precisely moves to the buffer zone to load the cardboard and transports it along a pre-set path to the conveyor belt docking point.

[Conveyor Belt Connection]

The conveyor belt starts up based on the arrival signal from the track vehicle, smoothly transferring the cardboard to the elevator entrance buffer zone, ensuring the cardboard is stacked neatly.

[Elevator Warehouse Entry]

After receiving the signal that the conveyor belt has completed its task, the elevator automatically rises to the target warehouse floor, completing the cardboard entry by using an integrated robotic arm or forklift device.

2. Application of I/O Modules

The system utilizes the PROFINET protocol, with the digital input module XB6S-1600 and the digital output module XB6S-0016B connected to the PLC via the coupler XB6S-PN2002, working in coordination to complete signal acquisition and execution output. The XB6S-1600 gathers signals from field sensors, including track vehicle arrival detection, conveyor belt operating status, and elevator floor positioning; the XB6S-0016B outputs signals to various actuators based on commands from the control system, assisting in tasks such as track vehicle start/stop, conveyor belt motor drive, and elevator lifting commands.

In traditional solutions, electromagnetic interference can easily lead to signal false alarms or equipment disconnections, and fault diagnosis relies on manual effort. Solidot's remote I/O modules not only ensure the real-time nature of signal acquisition and command output but also their strong anti-interference capability and intelligent diagnostic functions further highlight the product's practical value and stable reliability in complex industrial scenarios.

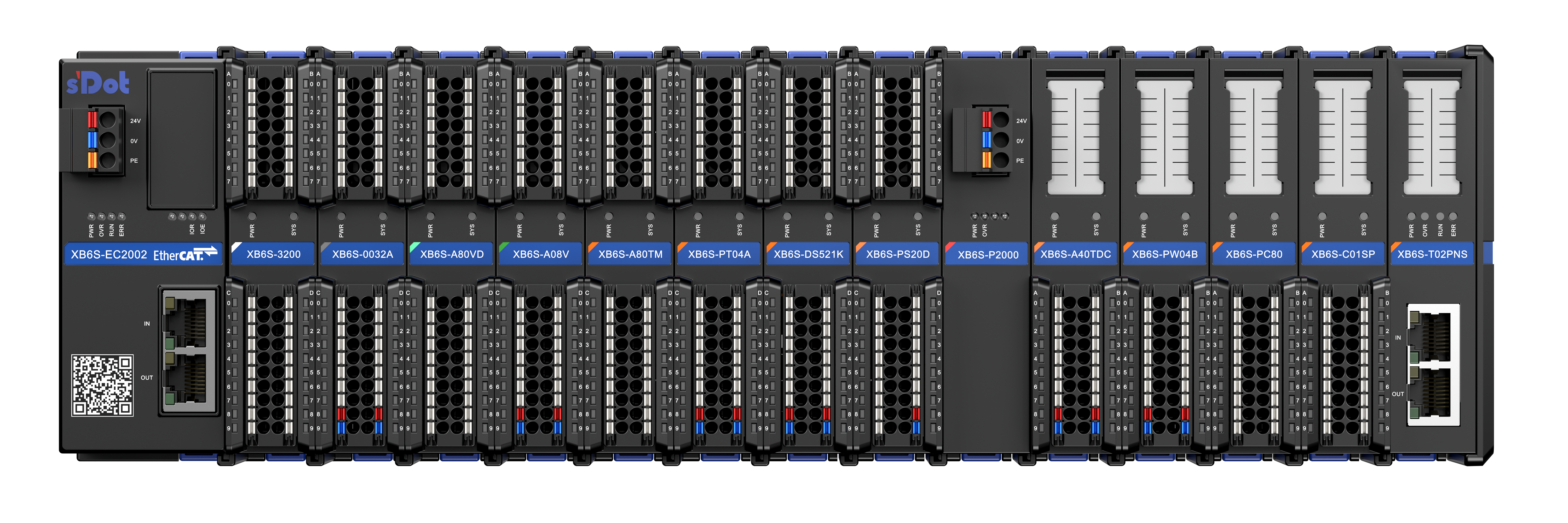

3. Highly Reliable Remote I/O Module XB6S Series Products

Solidot's remote I/O module XB6S series products are compatible with various bus protocols and possess functional modules for motion control, temperature acquisition, and more. The products undergo rigorous EMC testing, offering strong resistance to interference and preventing disconnections; they support diagnostics, alarms, and abnormal log recording, providing smart feedback and user-friendly operation.

Recommended Products

XB6S-PN2002

PROFINET filedbus coupler module

XB6S-1600

16-channel digital input module, input NPN/PNP compatible, input filter default 3ms

XB6S-0016B

16-channel digital output module, output PNP type