Application of Solidot PROFINET remote I/O module in cold chain three-dimensional warehousing

In the past three years of fighting against the novel coronavirus, no matter where the epidemic occurs, emergency response work has touched people's hearts. In addition, the supply of materials has also attracted more and more attention. On the one hand, it is difficult to buy vegetables, and residents' demand for fresh food has increased; on the other hand, the coronavirus vaccines and molecular diagnostics testing industry has accelerated development under the background of the epidemic, and the demand for medical cold chain logistics has surged. As a key link in the fight against the epidemic, the importance of cold chain logistics has been further highlighted.

In the cold chain logistics workflow, there are a large number of input and output signals that need to be collected on long-distance cold chain conveyor belts. Due to the different functions of different equipment stations, there are also pain points in signal collection. This article takes the actual application of the PROFINET protocol remote I/O module of SOLIDOT as a case study, focusing on the configuration of a stand-alone four-way shuttle balance car and a cold storage assembly line, fully demonstrating the flexibility of SOLIDOT plug-in I/O and the comprehensiveness of the integrated I/O. They are not only an indispensable "bridge" for complex and changeable industrial sites, but also a reliable pioneer that provides customers with high-quality solutions from small to large and from point to surface.

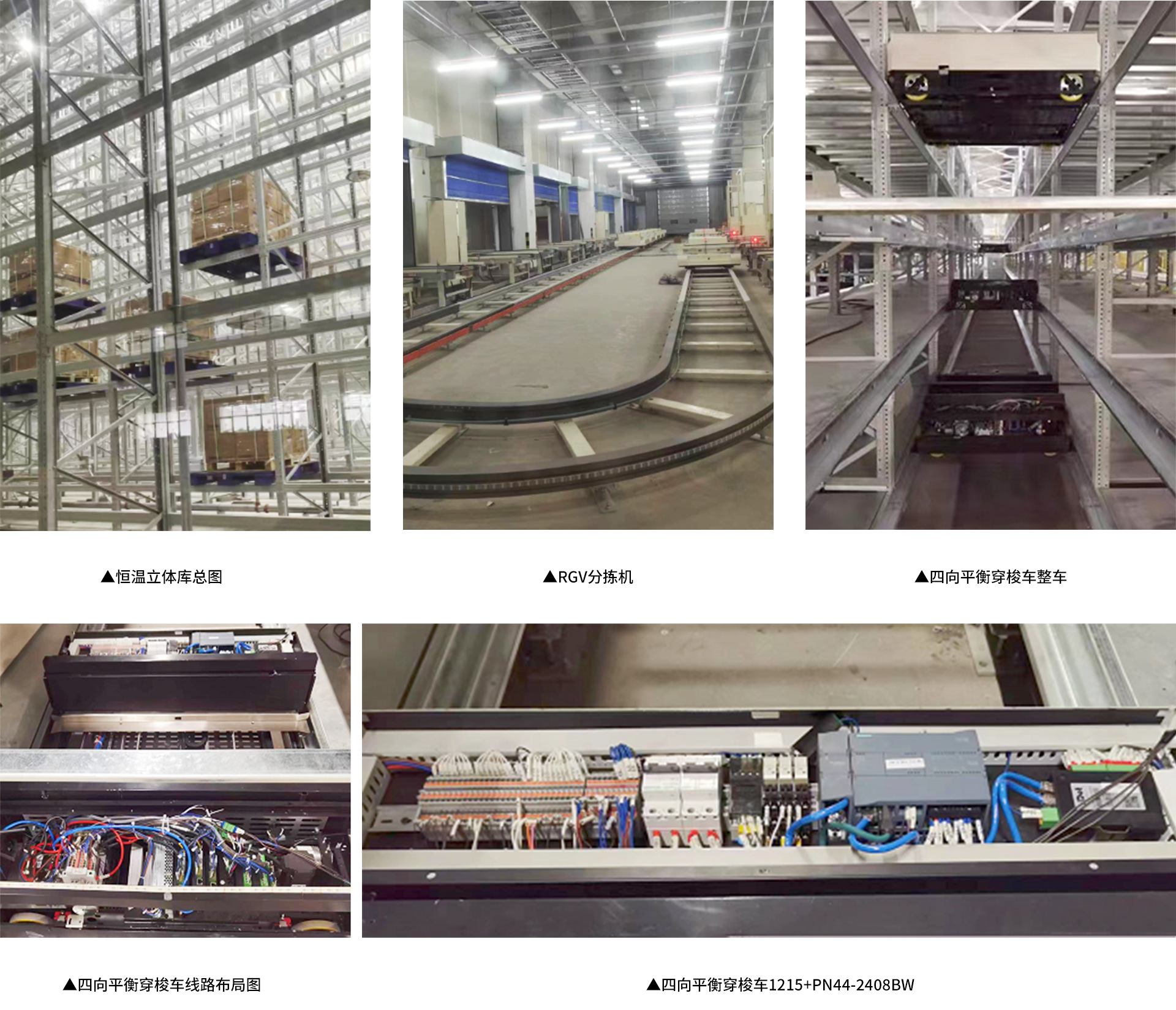

Application of PROFINET protocol products of SOLIDOT in cold chain logistics sorting equipment

Common equipment includes telescopic machines, flat conveyors, climbing conveyors, elevators, weighing belt conveyors, barcode scanning belt conveyors, pallet sorters, robot palletizers, AGV automatic transporters, RGV rail transporters, four-way shuttle balance vehicles, etc. The "brains" of these equipment mainly use Siemens 1516 PLC, and the stand-alone four-way balance shuttle vehicle uses 1215 PLC. The remote I/O uses the PROFINET protocol remote I/O module of SOLIDOT as the solution.

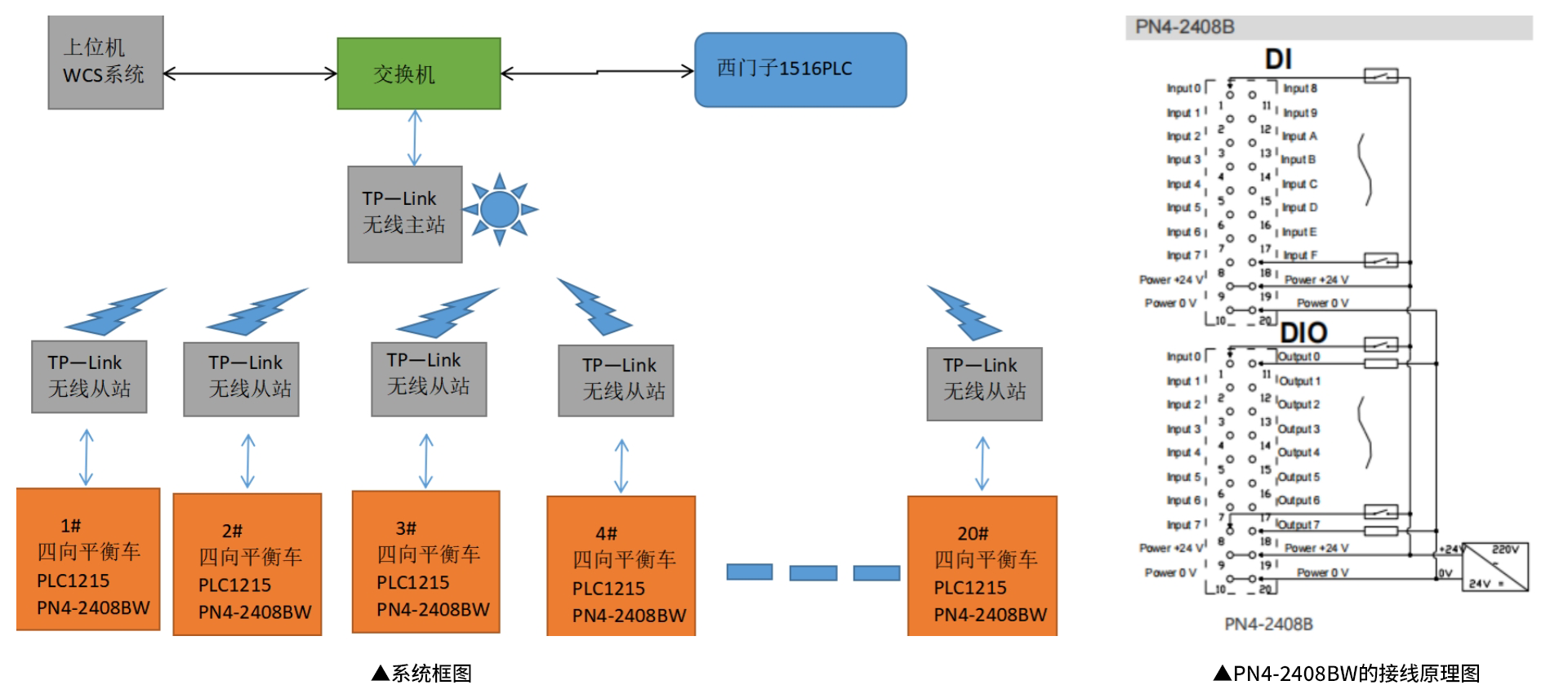

For stand-alone equipment with relatively small number of I/Os, such as four-way balanced shuttles, main cabinets, elevators, and RGV carts, an integrated I/O module PN4-2408BW was used on site. Specifically, the WCS system, the "brain core" of the storage equipment, sends the task to the 1516PLC, which communicates with the 1215 PLC of 20 four-way balance shuttle vehicles through wireless signals for intelligent I/O. The latter then collects the photoelectric information of the cart through the remote I/O module PN4-2408BW of SOLIDOT, thereby understanding the status of the goods and driving the cart to move.

▲ PN4-2408BW

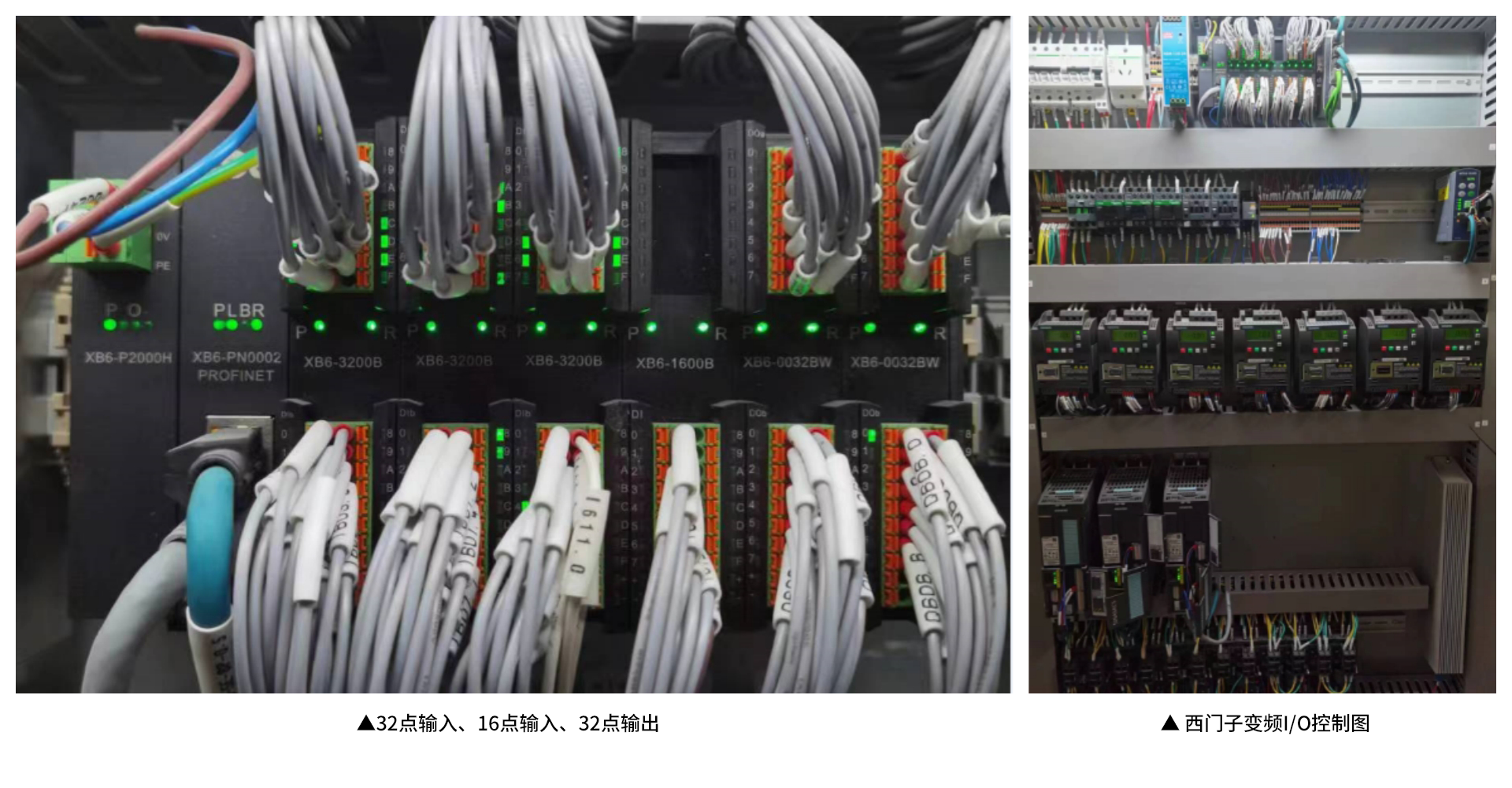

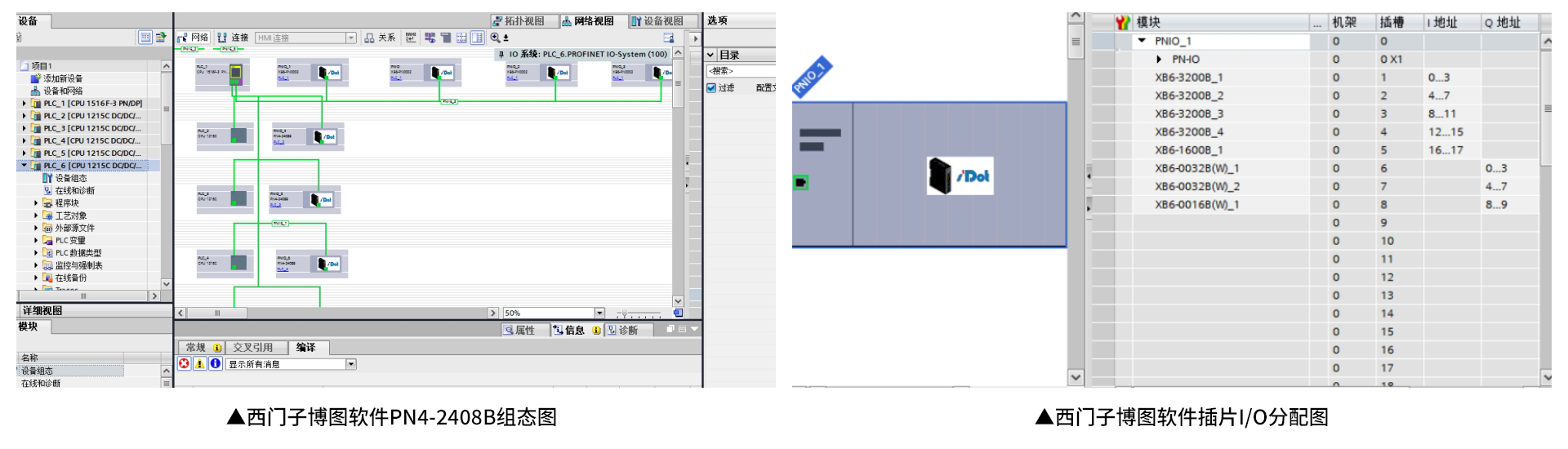

For other devices on site that need to collect a large number of input and output signals, we use the plug-in I/O modules of SOLIDOT, specifically: XB6-PN2002ST with integrated power supply and coupler, and XB6-1600B , XB6-3200B , XB6-0016BW , PN4-0032BW . In addition, electrical engineers can freely assemble I/O modules according to the actual situation on site, which is flexible and convenient.

SOLIDOT Remote I/O PLC Program Configuration Diagram

Intelligent cold chain logistics three-dimensional warehousing automation electronic control principle configuration description:

(1) A large number of photoelectric signals need to be collected at the cold chain logistics automation site, and the cargo information of the conveyor can be obtained through the feedback of photoelectric signals;

(2) The frequency conversion and contactor control signals of the long-distance cold chain belt conveyor are all controlled by the output signal;

(3) Emergency stop, proximity switch, travel switch, safety light curtain, button box, indicator light and other signals are all I/O signals.

We can add the GSD file of the PROFINET protocol of SOLIDOT to the TIA PORTAL software, and the configuration is very convenient. The following is the wiring diagram of the PN4-2408BW module:

Introduction to PROFINET protocol products of SOLIDOT

In the above-mentioned cold chain three-dimensional warehousing application, the photoelectric detection signal of the conveyor belt, the equipment arrival signal of the elevator, the safety signal, the control signal from cabinet, etc. all need to be collected. The remote I/O using the PROFINET protocol of SOLIDOT not only solves the customer's pain points, but also the product's excellent design and performance give the solution both flexibility and stability.

As a well-known domestic automation service provider, SOLIDOT has "early layout, solid foundation, and complete categories" in the field of domestic remote I/O. The integrated I/O module PN4-2408BW and plug-in I/O module XB6-PN2002ST used in this case are all independently developed. The former is aimed at small devices and a few points, while the latter solves the problem of free matching of multiple points. Both are classic products with a good reputation in the industry.

Over the years, SOLIDOT has always taken industrial bus as the core, providing better cost-effectiveness and better delivery cycle, and realizing continuous value output for customers. These high-quality products and cases not only demonstrate SOLIDOT's accumulation over the years, but also reflect the company's technical background of keeping pace with the times and standing at the forefront of the trend of industrial digitalization.

Recommended Products

XB6-3200B

32 DI, PNP, European style terminal

XB6-1600B

16 DI, PNP,European style terminal

XB6-0032B

32 DO,PNP,0.5A,European style terminal

XB6-0016B

16 DO, PNP, 0.5A, European style terminal

PN4-2408B

PROFINET, Intergrated I/O, 24DI, 8DO, PNP, 0.5A

XB6-PN2002ST

PROFINET Coupler kit (with power supply, end cover )