Application example of XB6S differential incremental encoder counting module of Solidot Technology slice IO module

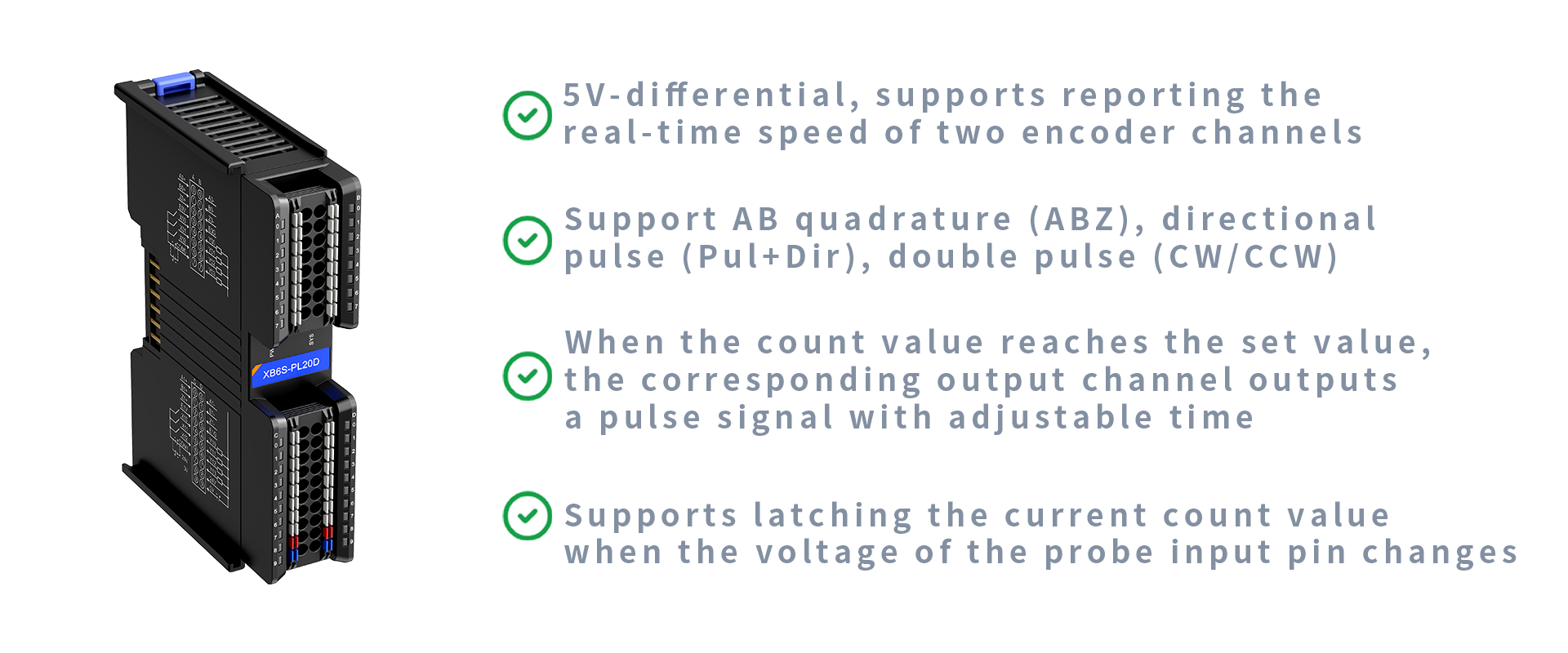

XB6S-PL20DIt is an XB6S series 2-channel incremental encoder counting module, which can be connected to two 5V differential incremental encoders to report real-time speed. It is compatible with the XB6S series coupler, and has three pulse modes to choose from: AB quadrature (ABZ), direction pulse (Pul+Dir), and double pulse (CW/CCW), and supports Z-phase clearing, comparison output, probe latching and other functions.

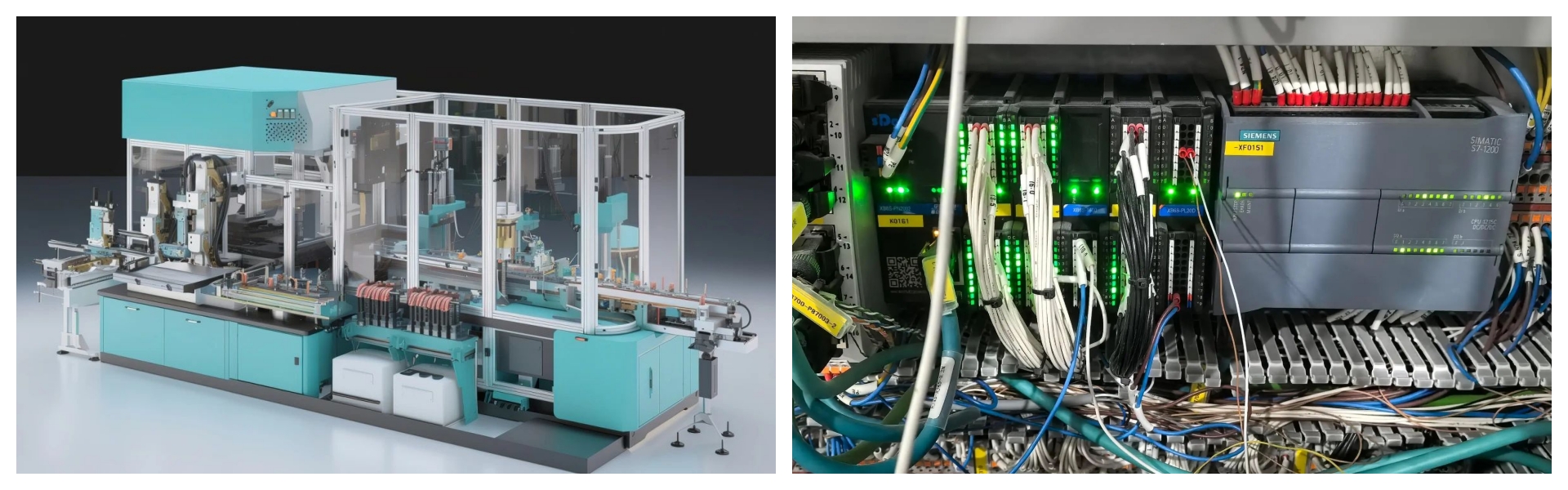

1. Application examples

The stator winding machine is a key equipment in motor manufacturing. It is used to accurately wind the copper wire onto the stator core. The quality of the winding will directly affect the performance and efficiency of the motor. When the winding machine is working, the manipulator or conveyor belt sends the stator core to the winding station, the servo motor moves according to the trajectory set by the program, and the winding head winds the copper wire into the core slot according to the preset number of turns and layers.

The XB6S-PL20D module of Solidot Technology can accurately collect the A-phase and B-phase orthogonal pulse signals of the encoder (built-in servo motor) to obtain direction and speed information, and the Z-phase signal is used to provide a reference point to ensure the accuracy of the starting position of the winding. It cooperates with the servo motor to realize closed-loop control, and can monitor and adjust the rotation speed and winding position in real time to ensure the winding quality.

XB6S-PL20D is also widely used in industrial automation, robotics, CNC machine tools and other scenarios that require differential signal incremental encoders.

Left: stator winding machine, right: XB6S-PL20D on-site application

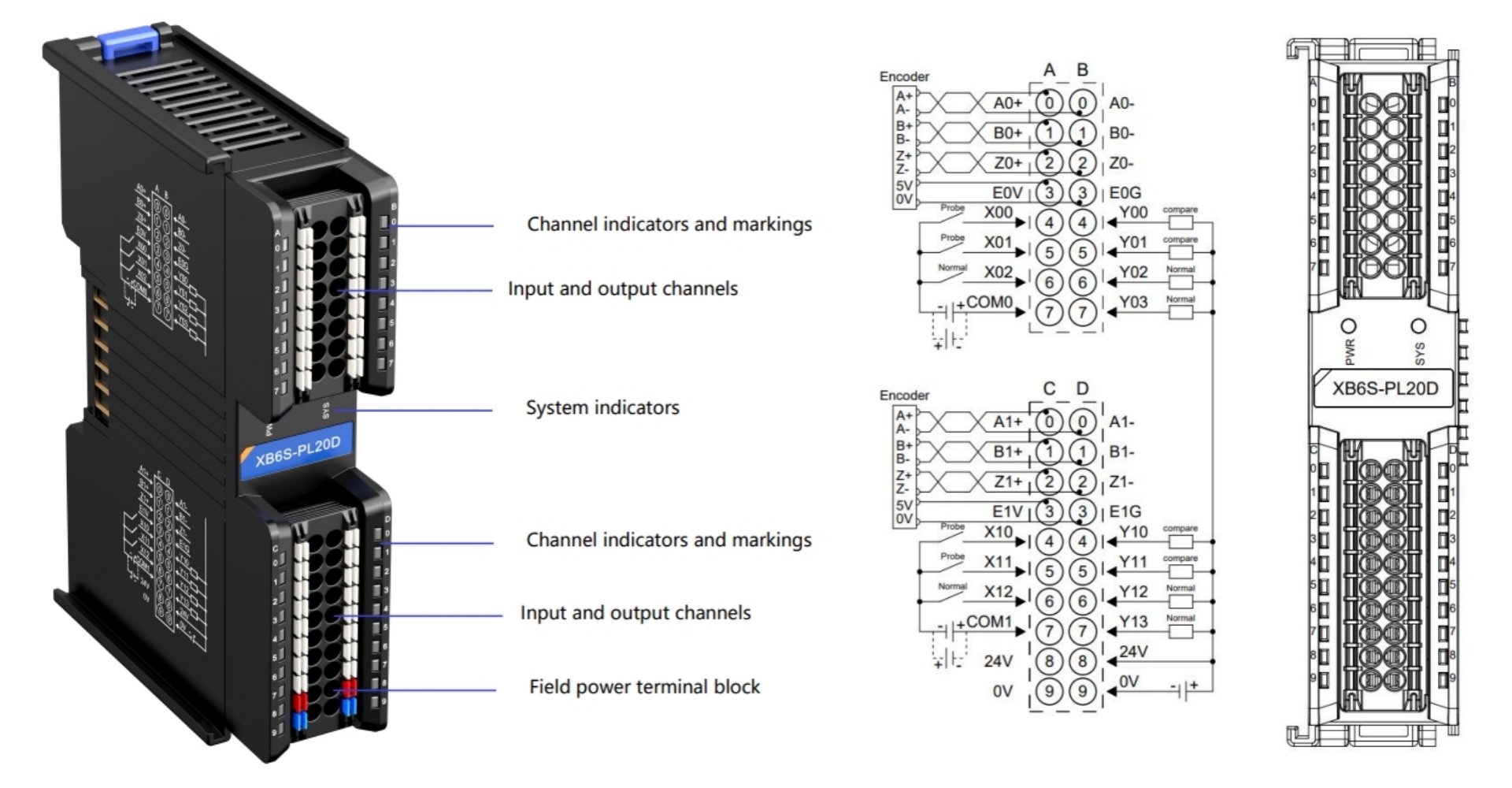

2. Panel structure and wiring diagram

Left: XB6S-PL20D panel structure, right: XB6S-PL20D wiring diagram

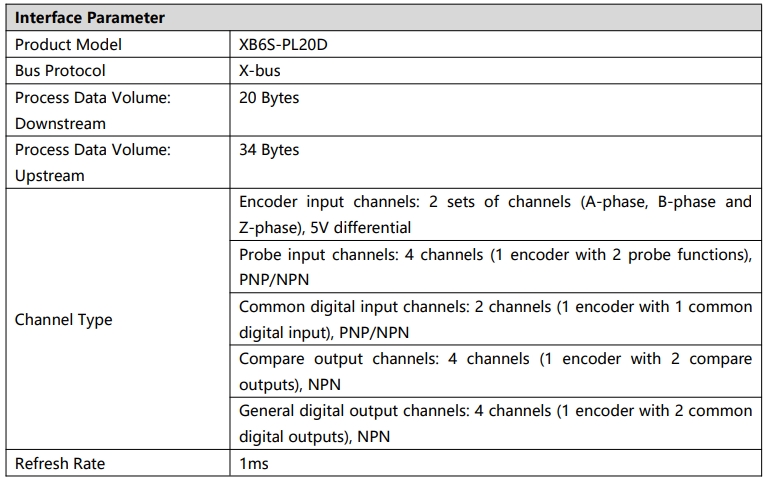

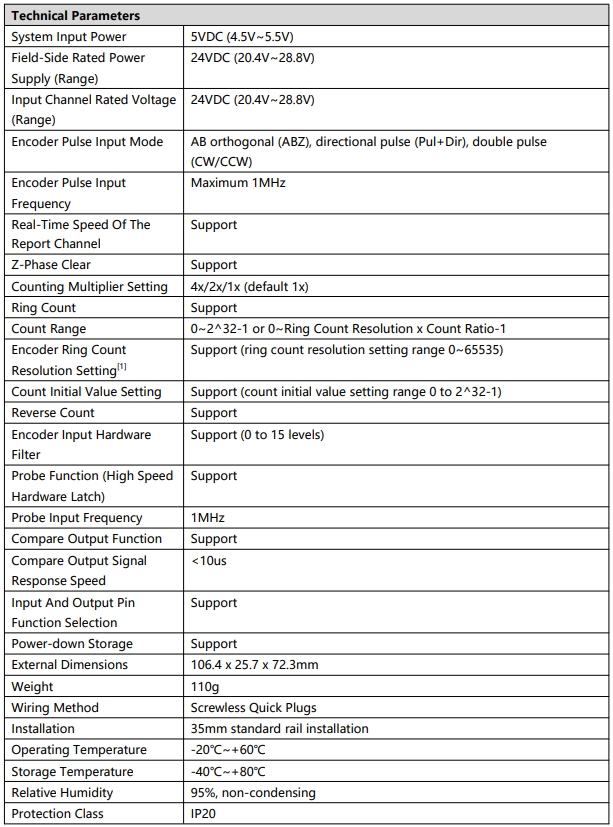

3. Parameters at a glance

Note [1]: The ring count resolution here is only used to set the ring count range of the encoder and is different from the physical resolution of the encoder itself.