Common problems and strategies for cables in CC-link networks

↑ Recommended CC-Link products from Solidot Technology

Figure 1: CC-Link slice I/O coupler set XB6-CL2002ST from Solidot Technology

Figure ② Solidot Technology CC-Link horizontal I/O CC3-3200

Figure ③ Solidot Technology CC-Link vertical I/O CC4-1616B

Figure ④ Solidot Technology CC-Link bus valve terminal C2S-CL-08B-S01

Figure ⑤ Solidot Technology CC-Link IP67 I/O CC7-0808B

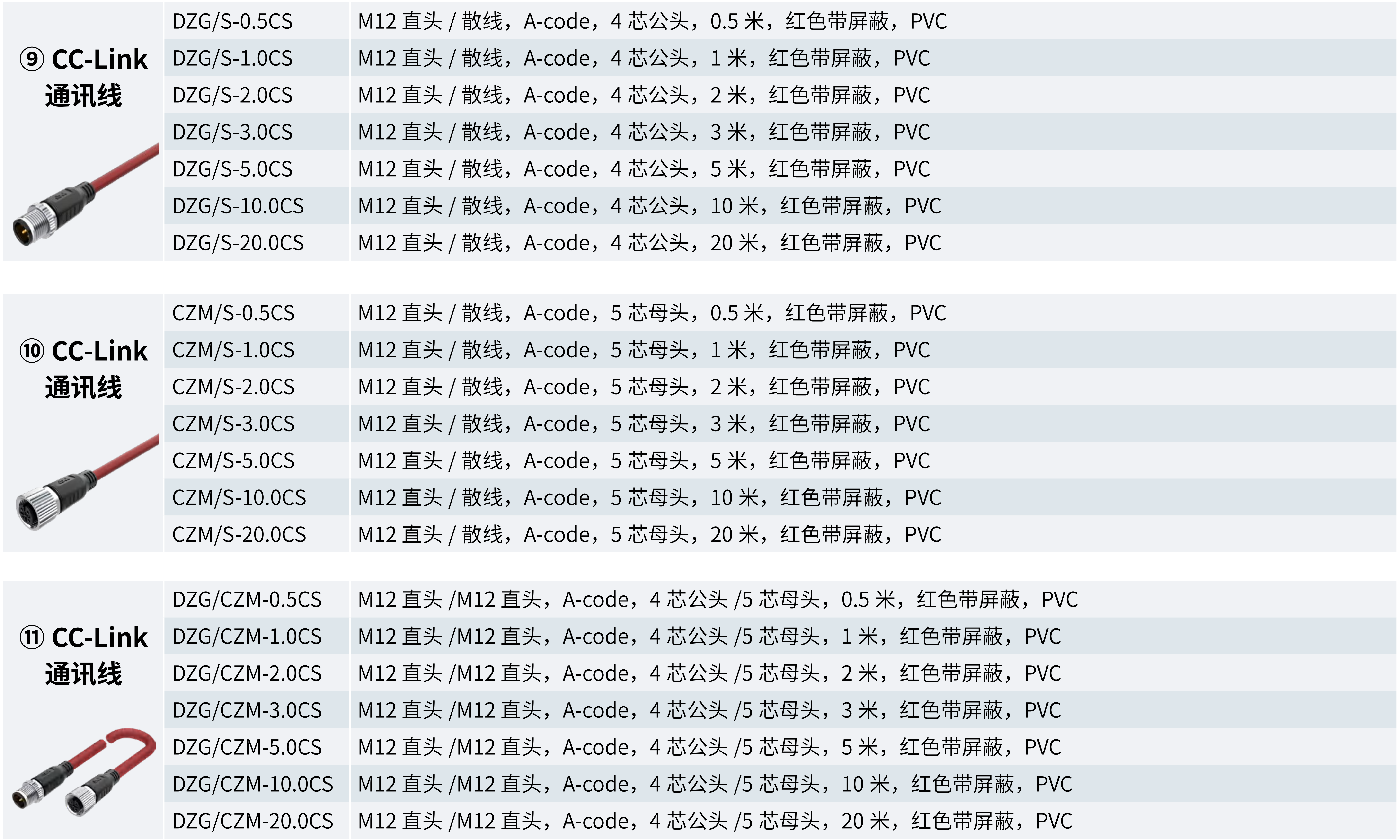

↑ Solidot Technology CC-Link communication cable

Applicable to bus valve island and CC7 series I/O module wiring

1. Overview of FAQ

*After power-on, the module loses a large area of line;

*After the servo motor is turned on, the module loses a large area of line;

*There is a fixed or random module drop-out and reconnection phenomenon in the line;

*Low rate delay>100ms, high rate will drop the line.

2. Analysis of cable problem causes and key points

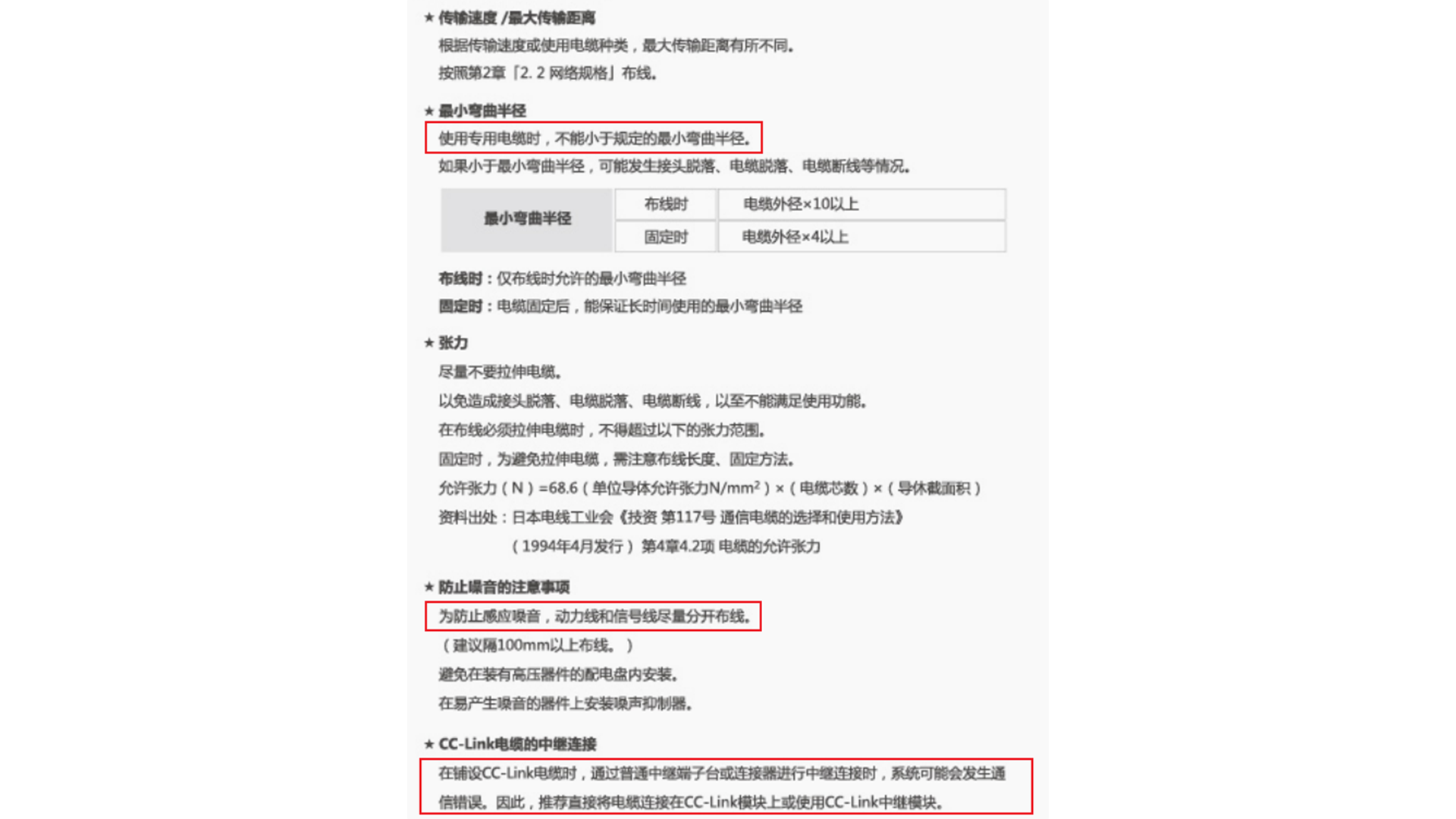

There are generally two main reasons: 1. Poor cable quality; 2. Irregular cable wiring. For details, see the key points in the screenshots of the "CC-Link Wiring Specifications" below.

According to the above situation, we need to pay attention to the following points when wiring:

* Use CC-Link certified and CC-Link Ver.1.10 compatible cable (characteristic impedance 110Ω, terminal resistance 110Ω)

* Communication lines and power lines are wired separately, and the spacing between wire troughs needs to be >20cm

* When Mitsubishi T-branch connectors are not used, only stations can be connected in series

* The terminal blocks sold on the market are very likely to cause crosstalk and packet loss, resulting in reduced communication quality. It is recommended to use FA sensor connector NECA4202 (IEC947-5-2) corresponding products

Note: NECA is the abbreviation of Japan Electrical Control Equipment Industry Association, and NECA4202 (IEC947-5-2) represents its related standards

*Try not to use terminal blocks for signal relays of non-T branch lines

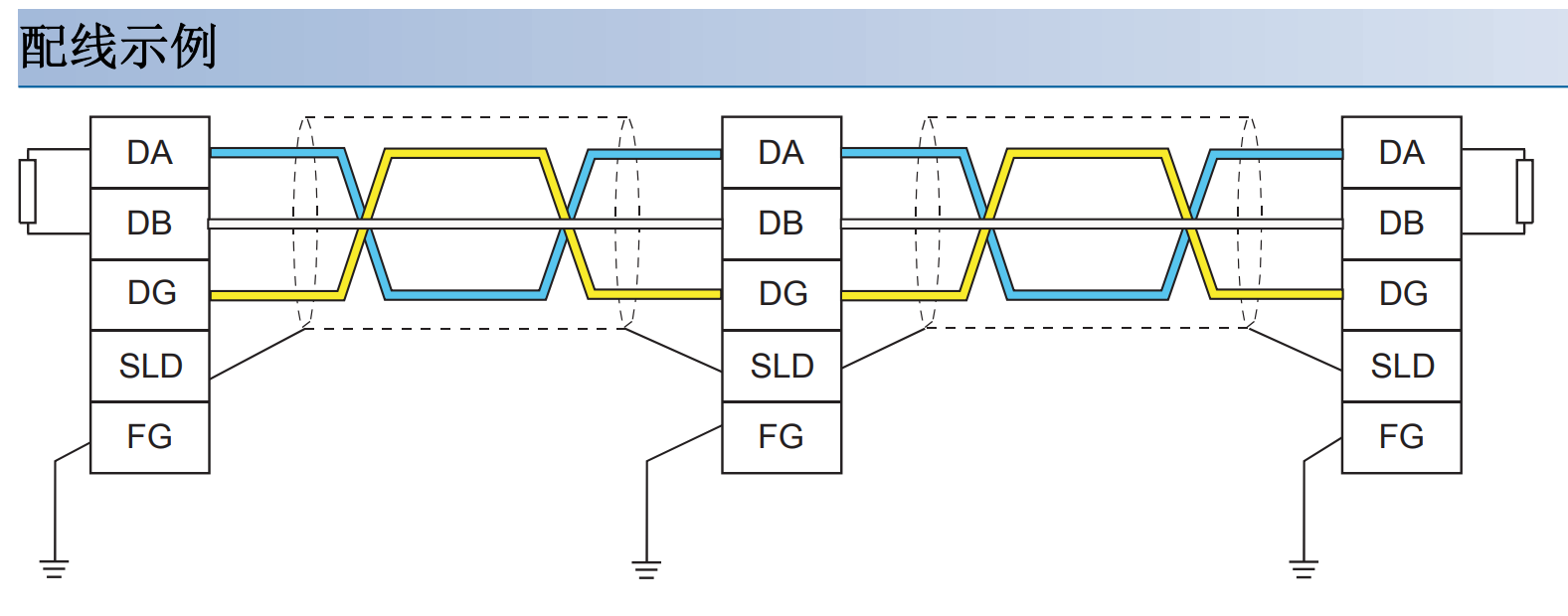

*Terminal resistors of 110Ω are connected to the ends of the trunk

Note: In the CC-Link network, the role of the terminal resistor is to eliminate signal reflection and ensure clear and reliable network data transmission. Since CC-Link is a digital bus protocol based on serial communication, it uses differential signal lines similar to coaxial cables to transmit data, which can cause signal reflection. In order to reduce the impact of signal reflection on signal transmission, a terminal resistor matching the signal characteristic impedance needs to be installed at both ends of each CC-Link bus. During the normal operation of the entire network, these resistors can help ensure the stability and reliability of network data transmission and reduce interference and bit error rate problems. Therefore, terminal resistors play a very important role in CC-Link networks. The following are related diagrams-

3. Cable problem troubleshooting methods

When the power is off, detect the impedance of the line connected between DA/DB. If the resistance value = 55±3Ω, it is normal (it can be measured directly between DA/DB on the PLC side). Otherwise, it is necessary to check whether the equipment in the line has abnormal resistance. Generally, there are the following types:

* The module DA/DB/DG is broken down, causing its own resistance to drop sharply (25.4KΩ between DA/DB of the I/O module of Solidot Technology, 80KΩ between DA/DB of the I/O block of Mitsubishi). It is recommended to replace the broken module directly;

* There is an abnormality in the CC-Link cable, and the cable-to-ground resistance is ≠∞. It is recommended to replace the cable directly;

* The total length of the on-site cable is greater than the longest communication distance at the current rate. It is recommended to reduce the rate or rewire the cable.