Application of the Solidot EtherCAT remote I/O in the aspect of appearance inspection and measurement of machined parts

In recent years, under the strong support of the government, "Made in China 2025" strategy implementation is quite effective, China's rapid development of intelligent manufacturing, machinery manufacturing using automation technology to transform the equipment to achieve the equipment can be self-sustainable automatic production, processing, optimization and other processes, the digital transformation of various industries with promising results.

After the empowerment of automation technology, the traditional industry has ushered in a qualitative leap in terms of high quality, high quantity and improved work efficiency. This article takes two actual cases of 2D camera and 3D inspection profilometer in industrial detection as the cut-in point, introduces in detail the high quality solutions provided by SOLIDOT's remote I/O, and also highlights the graceful bearing of SOLIDOT under the banner of intelligent manufacturing.

SOLIDOT Remote I/O in 2D Camera Systems

1. Diagram of OMRON NX1P2 PLC-controlled precision detection equipment

Small components precision detection equipment using HIKVISION industrial 2D camera, for the different vision of the product, different sizes, through the servo-driven camera for up and down positioning, able to match the detection of different products.

▲Precision components detection equipment

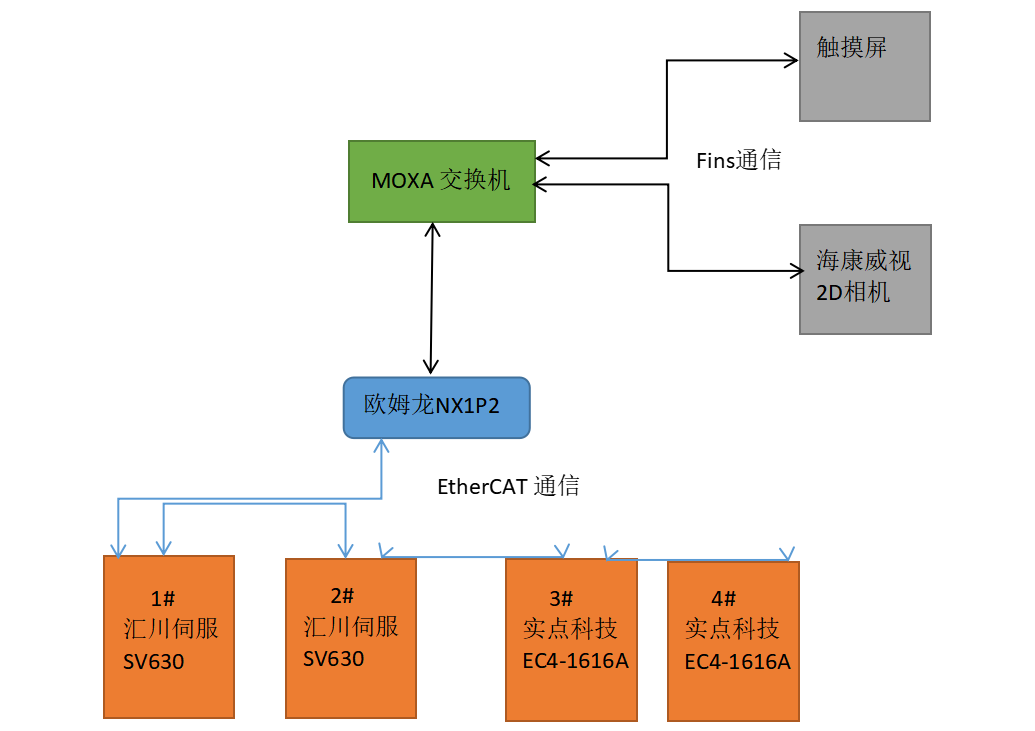

2、Description of control principle and system block diagram

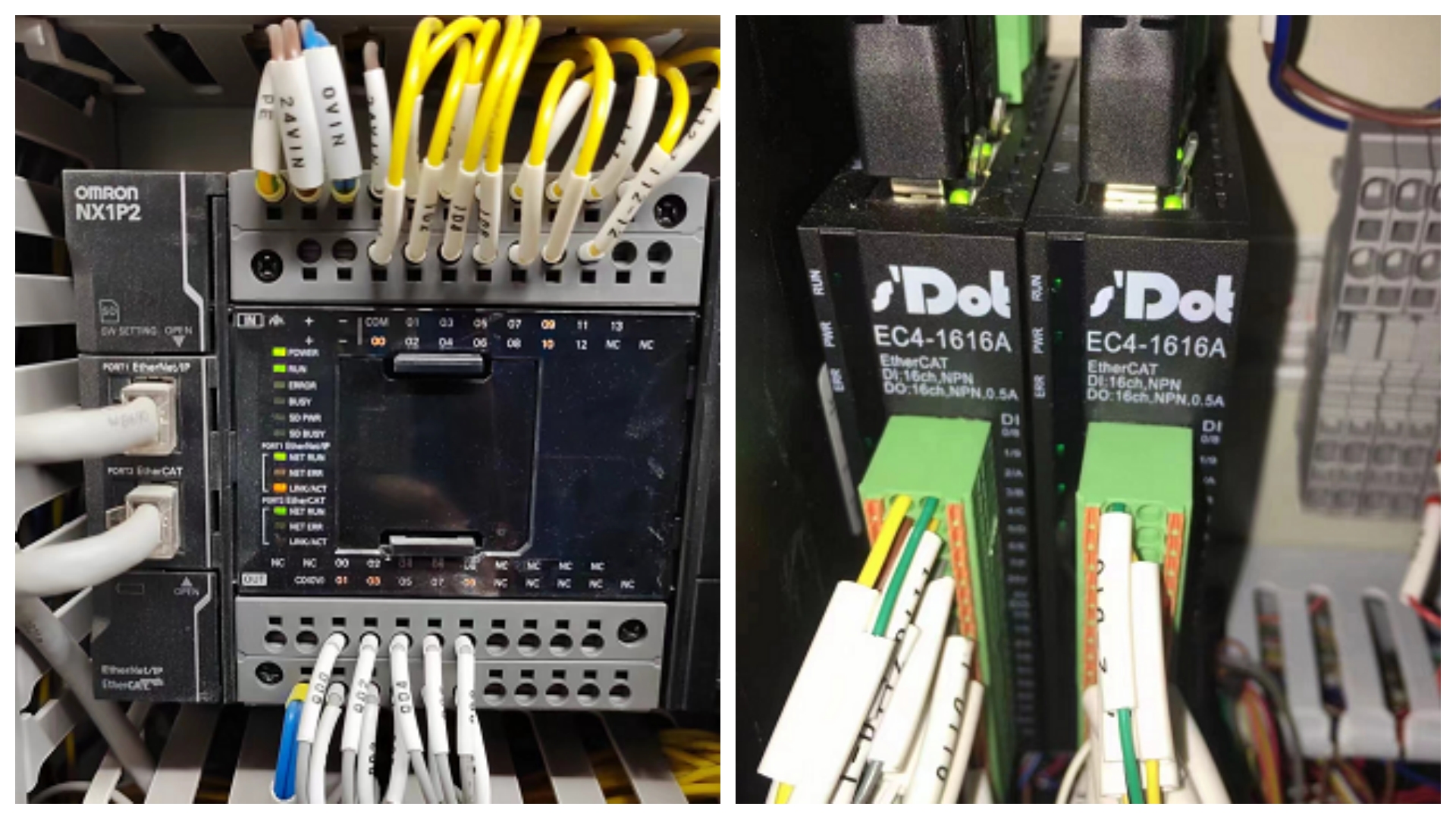

The detection equipment adopts OMRON NX1P2 PLC as the EtherCAT master to control the servo to realize the up and down movement of the HIKVISION 2D camera; while the peripheral switching signals, such as the product's detection photoelectric signals, the servo's upper and lower limit and home signals, and peripheral pushbuttons and indicator signals, etc., are captured by two SOLIDOT EC4-1616A Remote I/O Modules.

Through OMRON's Fins protocol to communicate with HIKVISION's 2D camera, the camera is triggered to perform photo-taking action, and the generated image is then processed by the camera's algorithm to send the final OK and NG signals to PLC, and if the PLC receives the NG signal, the alarm will be prompted by driving the alarm lamp through the output signal of the SOLIDOT EC4-1616A Remote I/O Module.

▲PLC and remote I/O EC4-1616A

▲Diagram of electrical control system

SOLIDOT Remote I/O in 3D Profilometer

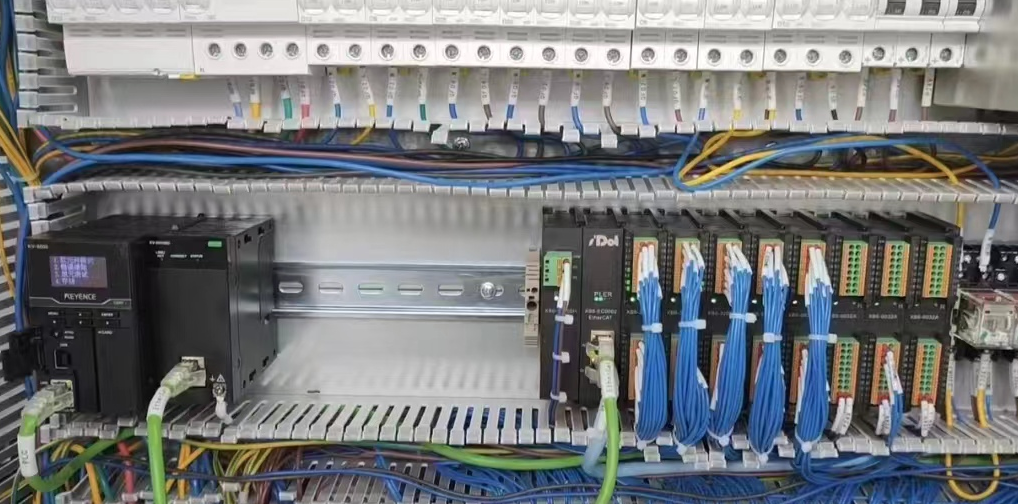

1, KEYENCE KV-8000 PLC controls 3D profilometer equipment

The detection equipment is based on a KUKA robot that picks up the material from the loading logistic and places it on a selector table for inspection. After the inspection, it is then picked up by the robot and moved to a rotary indexer for inspection, and finally the robot picks up the material and places it on the unloading logistic.

▲Automatic loading and unloading of KUKA robots

2、Description of control principle

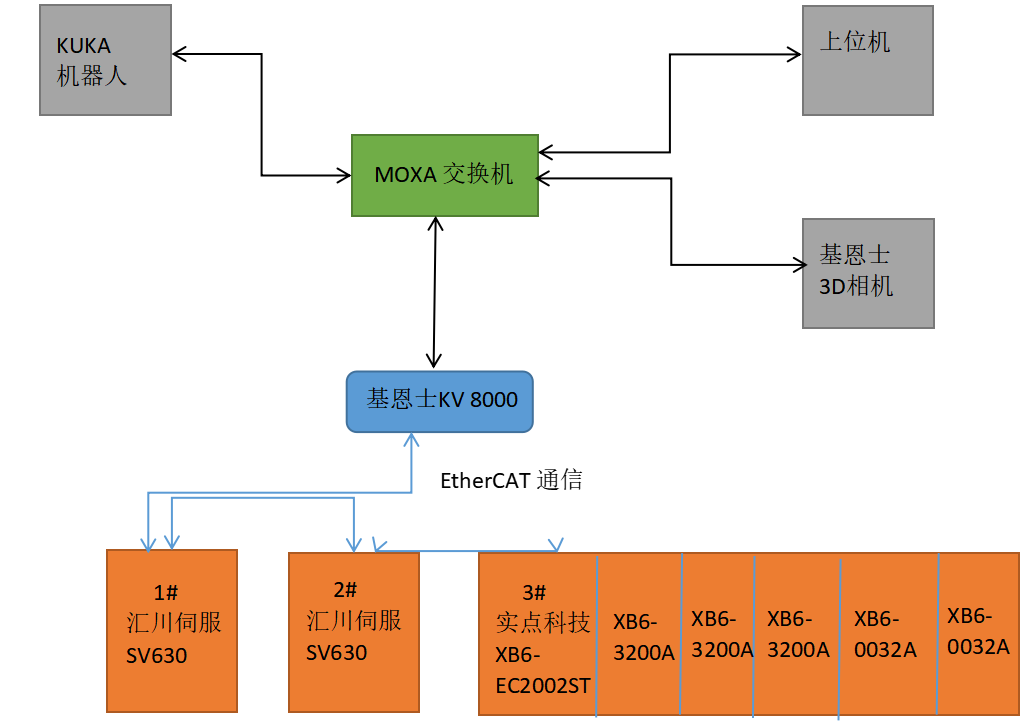

The detection equipment adopts KEYENCE KV-8000 PLC as the EtherCAT master to control the servo to realize the forward and backward and up and down movement of the KEYENCE 3D profilometer. The peripheral switching signals, such as product detection photoelectric signals, servo upper and lower limit and home signals, peripheral pushbuttons and indicator lights, are collected through the SOLIDOT EtherCAT protocol plug-in I/O Module XB6-EC2002ST , XB6-3200A , XB6-0032A .

The PLC communicates with the KUKA robot through the EtherNet/IP protocol to realize the interaction of the robot's gripping request and unloading request signals. The PLC also communicates with the host computer through this protocol. The host computer receives the scanning signal from the PLC and drives the 3D profilometer through command control, then the scanned data from the 3D profilometer is fed back to the host computer in real time, and then the data processing of the image is carried out to get the measurement data of the actual product to generate the point cloud diagram.

▲ Plug-in XB6-EC2002ST

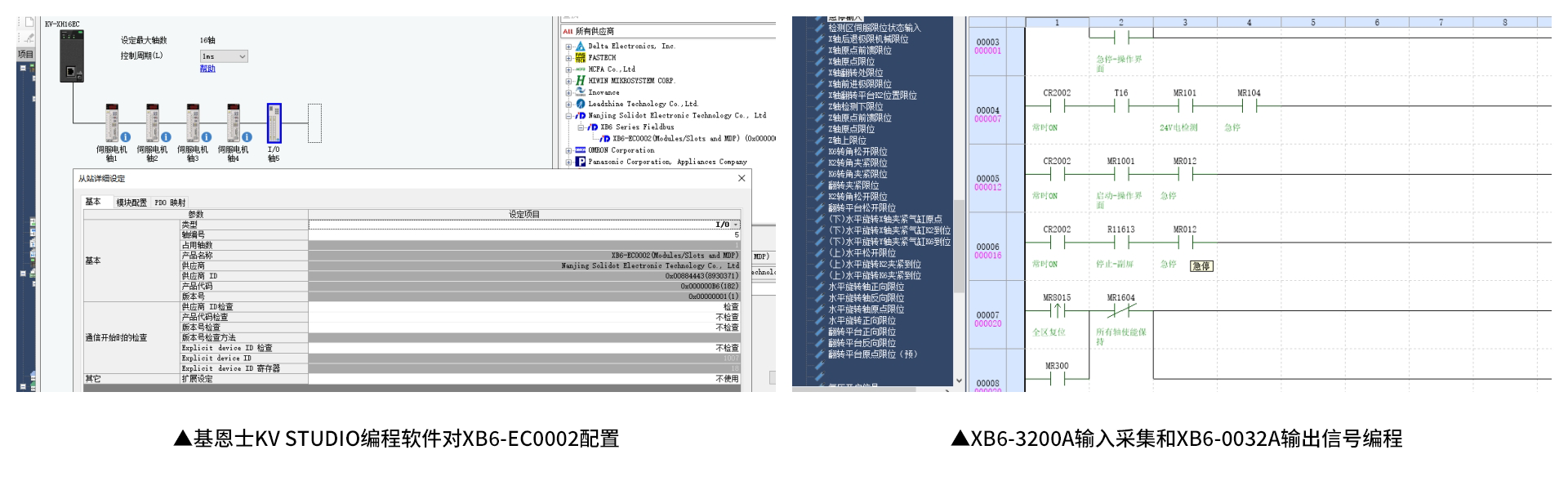

3、KEYENCE KV STUDIO programming software configuration and system block diagram

The KV-8000 PLC comes with a network interface that integrates TCP/IP and EtherNet/IP protocols, while the EtherCAT protocol motion control and remote I/O are realized by the KV-XH16EC module.

▲ System block diagram

Introducing SOLIDOT EC4 and XB6 Series Products

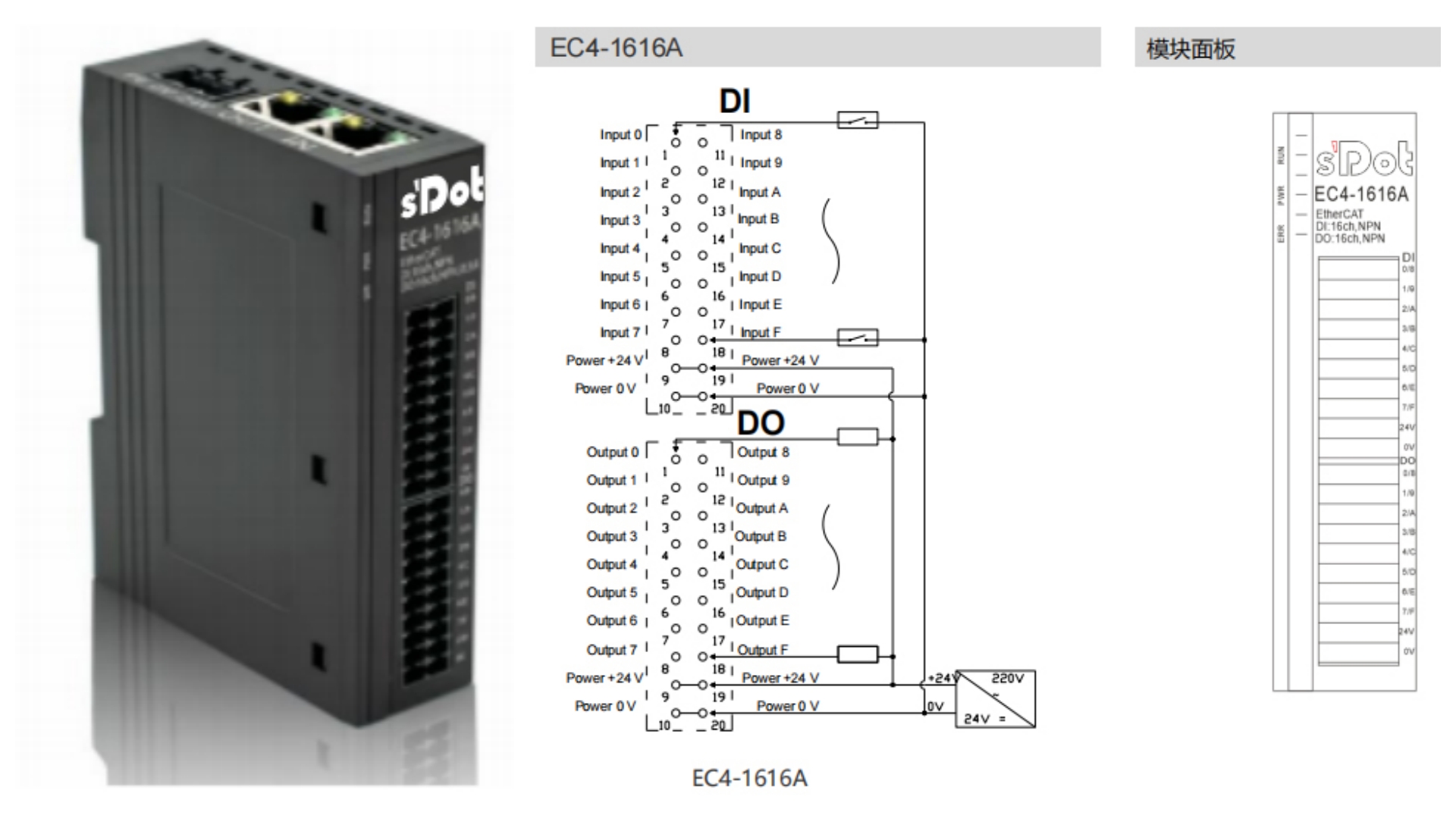

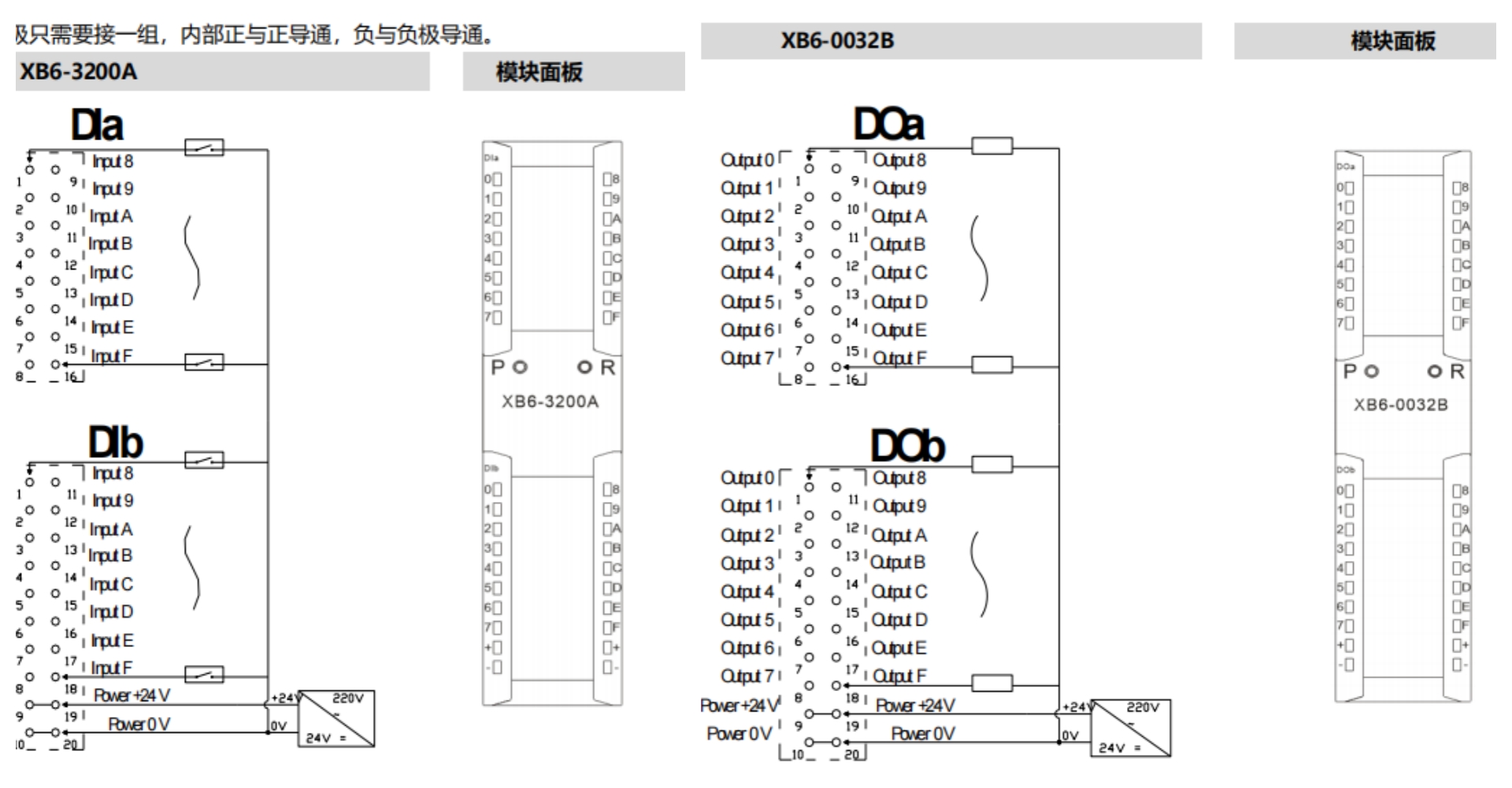

SOLIDOT Intgerated I/O modules EC4-1616A and plug-in I/O modules XB6-EC2002ST, XB6-3200A, XB6-0032A have good performance in the above two cases, they are also the representative products of EC4 series and XB6 series, which are widely used in various industries.

▲ Integrated EC4-1616A

▲ Plug-in XB6-EC2002ST

▲ XB6-3200A and XB6-0032A wiring diagrams

SOLIDOT EC4 series integrated I/O module, based on EtherCAT industrial Ethernet bus, the product structure is compact and occupies little space, only 102mm×72mm×25mm, is the king of flexibility in configuration; XB6 series plug-in I/O module, the coupler and I/O module combination of the design structure is scientific and practical, and the communication backplane adopts the X-bus bus, and the scanning period is XB6 series plug-in I/O modules, with a scientific and practical design structure of coupler and I/O module combination, communication backplane using X-bus bus, and scanning cycle of up to 1ms, are the versatile players with both extensibility and transmission rate.

Whether integrated or plug-in type, SOLIDOT I/O modules have the advantages of high real-time, rich module types, easy configuration and diagnosis, etc., which provide a wide range of choices and solid guarantee for customers' high-speed data acquisition, optimized system configuration, simplified on-site wiring, and improved system reliability, and continue to write the case of "Professionalism Creates Value" one after another in various industries.

Recommended Products

EC4-1616A

EtherCAT, Integrated I/O, 16DI, 16DO, NPN, 0.5A

XB6-3200A

32 DI, NPN, European style terminal

XB6-0032A

32 DO, NPN, 0.5A, European style terminal

XB6-EC2002ST

EtherCAT coupler kit:inclue EtherCAT coupler(XB6-EC0002)、2A power supply(XB6-P2000H)、end cover( XB6-CVR00)